Transfer conveyors keep your operations running smoothly by moving products seamlessly from one stage to the next. From delicate items that require gentle handling to high-volume lines that demand speed and precision, transfer systems help eliminate jams, reduce product damage, and improve overall efficiency. With the right transfer solution from Dynamic Conveyor, you can streamline flow, protect product quality, and keep your production lines performing at their best.

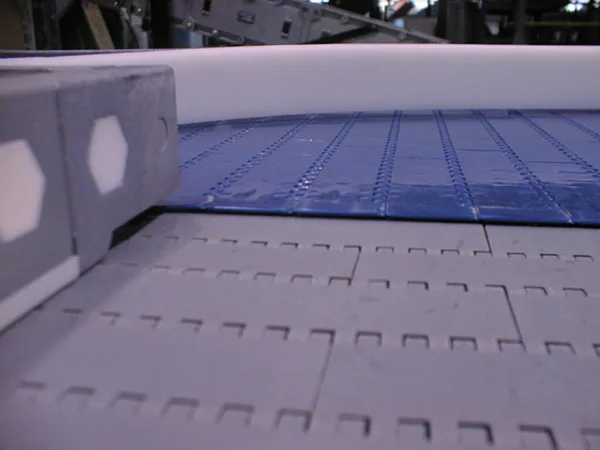

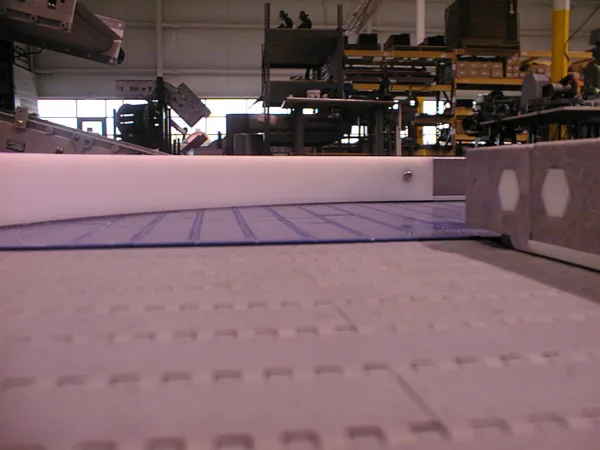

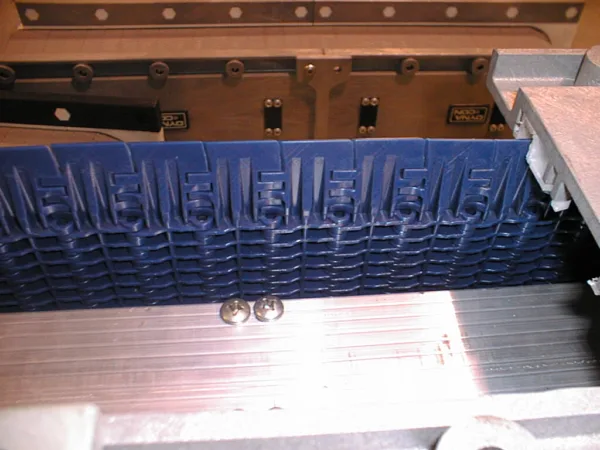

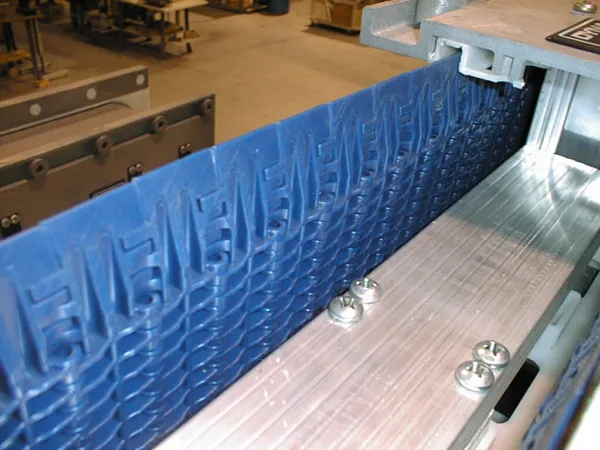

Knife Edge Transfer System:

When precision matters, knife edge transfers (also called nosebar or knife-edge idler transfers) provide the smooth handoff your products need. Designed for small or delicate items, these systems minimize the gap between conveyors to maintain product orientation and stability. The result: fewer jams, drops, or misalignments—keeping your line efficient and your products protected.

Inline Merge Transfer Conveyor Systems:

Speed up your operations and reduce bottlenecks with inline merge transfers. By combining multiple conveyor lines into one, these systems keep product flow organized and predictable. Built-in sensors and metering belts feed items at carefully timed intervals, preventing backups while maximizing throughput. They’re an ideal fit for packaging, distribution, and high-volume facilities where uptime and efficiency drive profitability.

Waterfall Transfer:

Gravity does the work in waterfall transfers, making them both simple and reliable. Products flow from one level to another via a controlled drop, with chute angle and height engineered to reduce impact and prevent bouncing or breakage. Whether you’re handling energy bars, packaged goods, or bulk materials, waterfall transfers deliver low-maintenance performance with consistent results.

Dead Plate Transfer:

For stable, rigid items, dead plate transfers offer a straightforward way to move products across conveyor gaps. The stationary plate creates a bridge that lets items slide smoothly from one belt to the next. It’s a cost-effective solution that works well in slower or steady-paced lines, though best applied where products are uniform and unlikely to shift out of place.

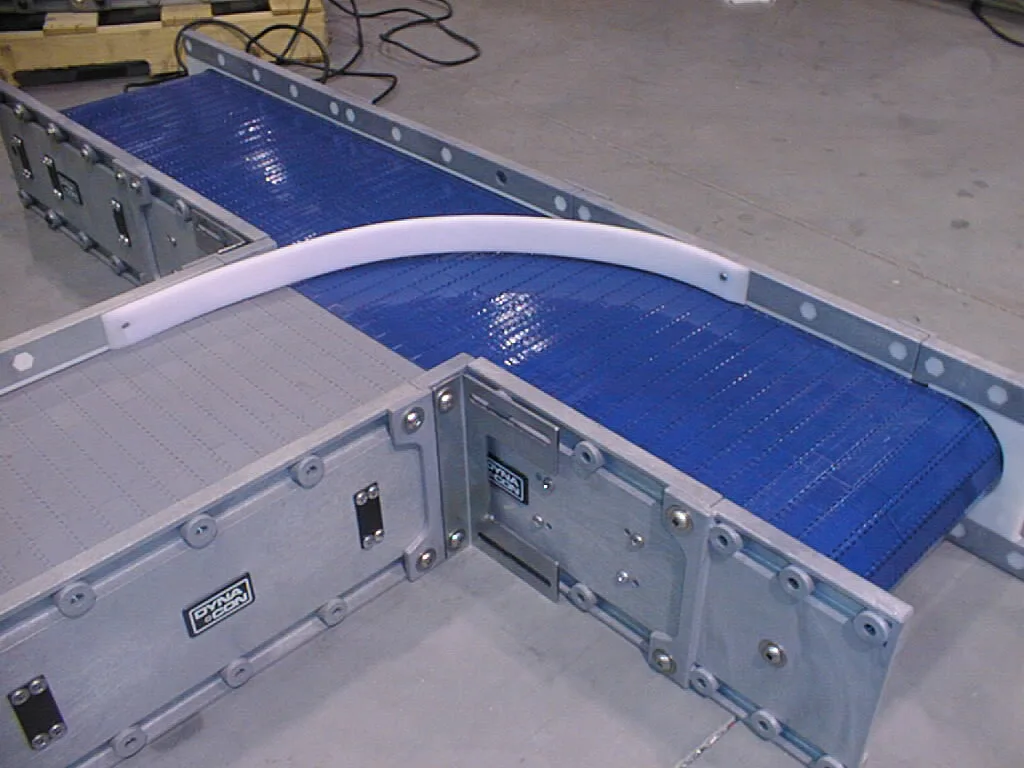

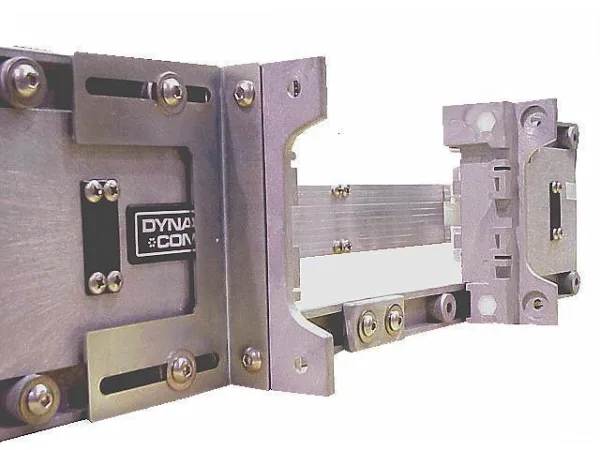

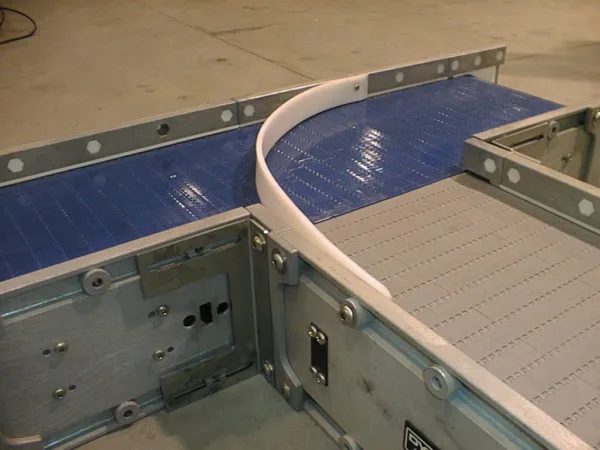

ARB Right Angle Transfer:

Take product control to the next level with ARB (Activated Roller Belt) right angle transfers. Using rollers embedded in the belt, activated by a system beneath, these conveyors redirect products at precise 90-degree angles—or in multiple directions—without bulky mechanical arms. Perfect for turning, merging, and sorting in packaging and material handling environments, ARB conveyors deliver flexibility, reliability, and efficiency with minimal moving parts.

Seamless Product Flow Between Conveyor Lines

Dynamic Conveyor’s Transfer Conveyors are engineered to ensure smooth, efficient transitions between conveyor systems. Whether you’re moving small, delicate items or managing high-volume packaging production lines, our transfer solutions are designed to maintain product integrity and streamline operations. With a wide range of transfer conveyor types available, you can customize your system to meet the unique needs of your application.

Transfer Conveyor Solutions Across Industries

Food Processing: Knife edge transfer conveyors gently move food items from one line to another using knife edge transfers to prevent product damage.

Packaging: Inline merge transfers combine multiple packaging lines into a lane often prior to packaging or taper machines.

Automotive: Waterfall transfers allow small, stamped metal or plastic parts to seamlessly transfer between two conveyors or to / from conveyors and ancillary equipment.

Consumer Goods: ARB right angle transfers redirect boxed products efficiently into different lanes for sortation and distribution.

Pharmaceutical: Dead plate transfers allow for cost effective of transfer between multiple conveyor lines in a cost effective manner.

Benefits of Transfer Conveyors from Dynamic Conveyor

Improved Product Handling: Minimize damage and ability to maintain orientation during transitions with precision-engineered transfer solutions.

Customizable Configurations: Choose from a variety of transfer types to suit your product size, shape, and production flow.

Modular Design: Easily integrate with existing conveyor systems and reconfigure as your needs evolve.

Reduced Downtime: Reliable, low-maintenance components keep your line moving efficiently.

Sanitary Options Available: Designed with cleanability in mind for food, pharmaceutical, and other hygiene-sensitive industries. (Link to Sanitation and Washdown Apps Page)

Let’s Build Your Ideal Transfer System

Whether you’re looking to merge lines, change direction, or elevate your product flow, Dynamic Conveyor’s Transfer Conveyors offer the flexibility and performance you need. Contact us today to discuss your application and discover how we can help optimize your production line.