Get Exactly What You Need Every Time

Hybrid specialty conveyors are custom designed specifically to meet the most demanding conveyance objectives. Some of the most common challenges that require specialty conveyor solutions include:

- limited space

- high speeds

- heavy loads

- high impact

- abrasive products

- delicate products

- temperature extremes

- high or low PH products

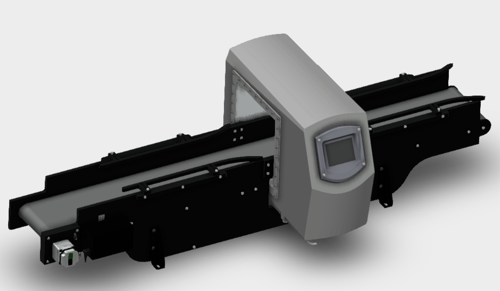

Our Team will take the time to understand your specific products and unique needs. The ideal concept is then developed for each conveyor design and the resulting conveyor solution will meet the form, fit and function required for your unique application. A 3D conveyor drawing of each specialty conveyor system is provided during the quote stage so you can understand how we will solve your biggest conveyance challenges.

Configurations

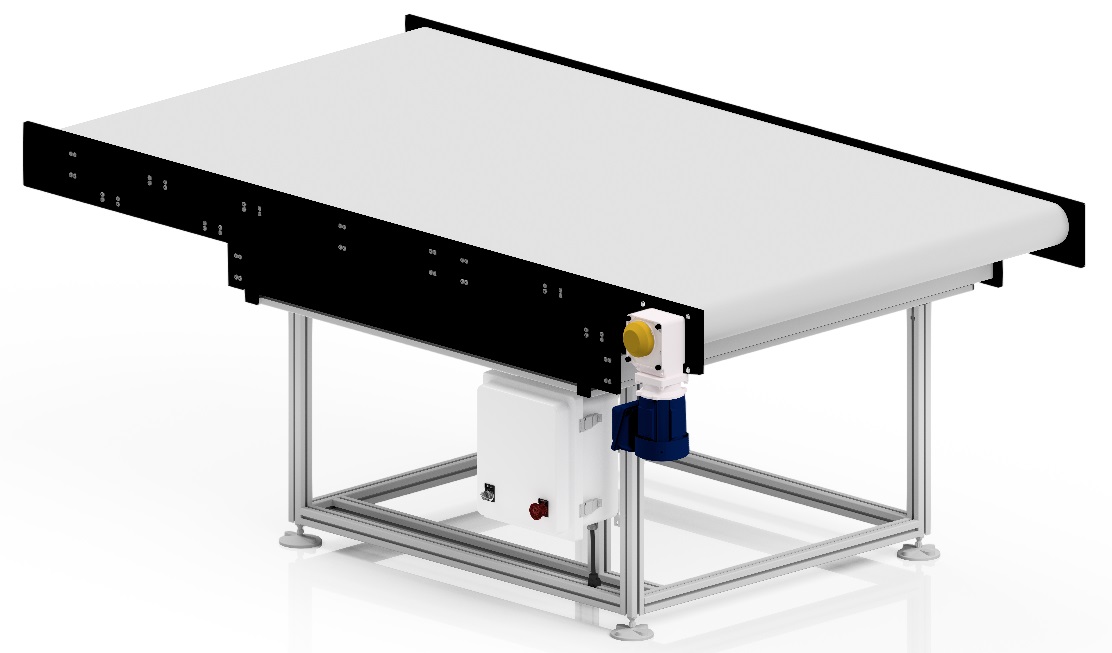

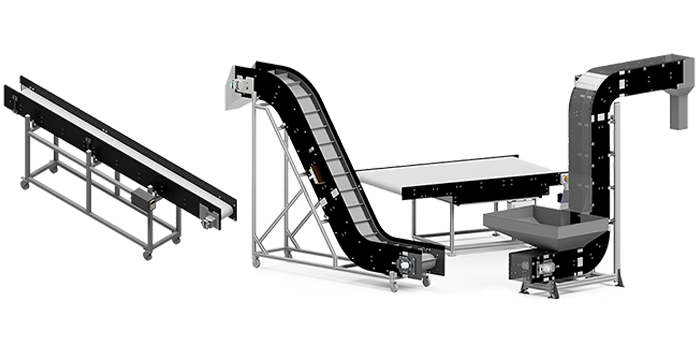

Flat Conveyors

A Hybrid flat conveyor is anything but basic, built to meet the toughest demands of your conveyance objectives.

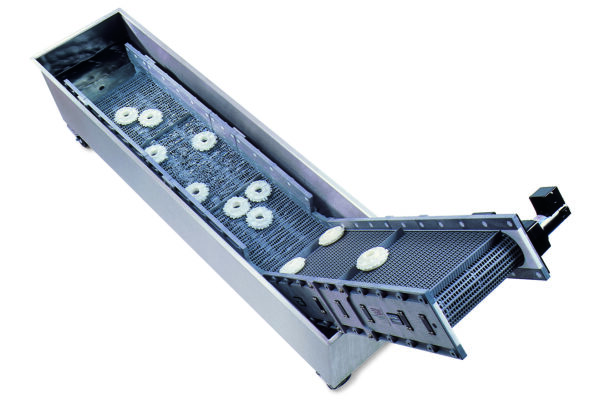

Z Conveyors

Z conveyors can be built using angles ranging from 30o to 90o, creating the custom configuration to get your product exactly where it needs to be.

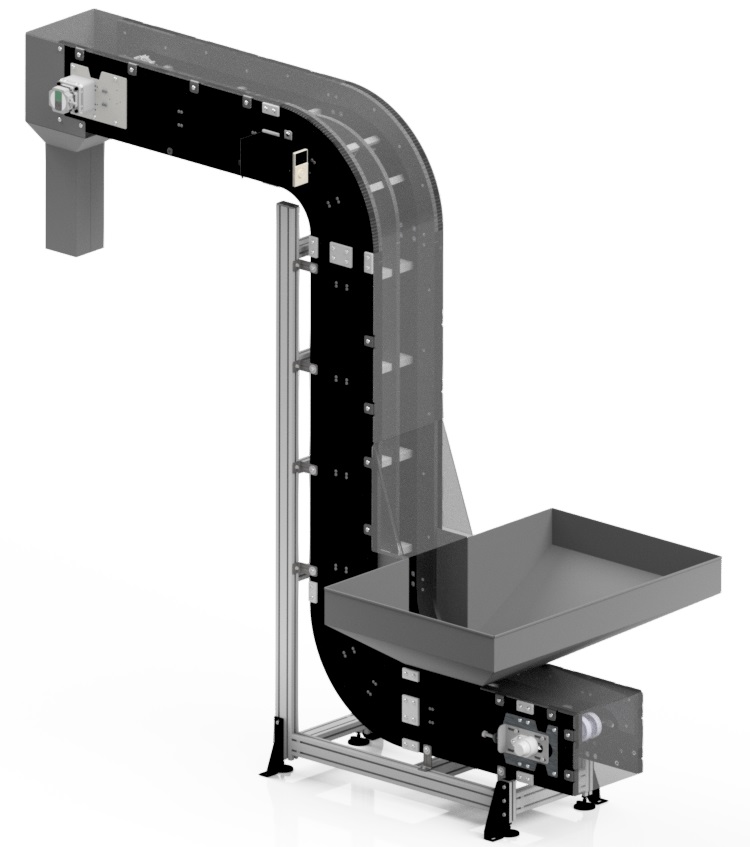

Vertical Conveyors

Hybrid vertical conveyors gives you the ability to maximize floorspace and efficiently convey products of all kinds to their final destination.

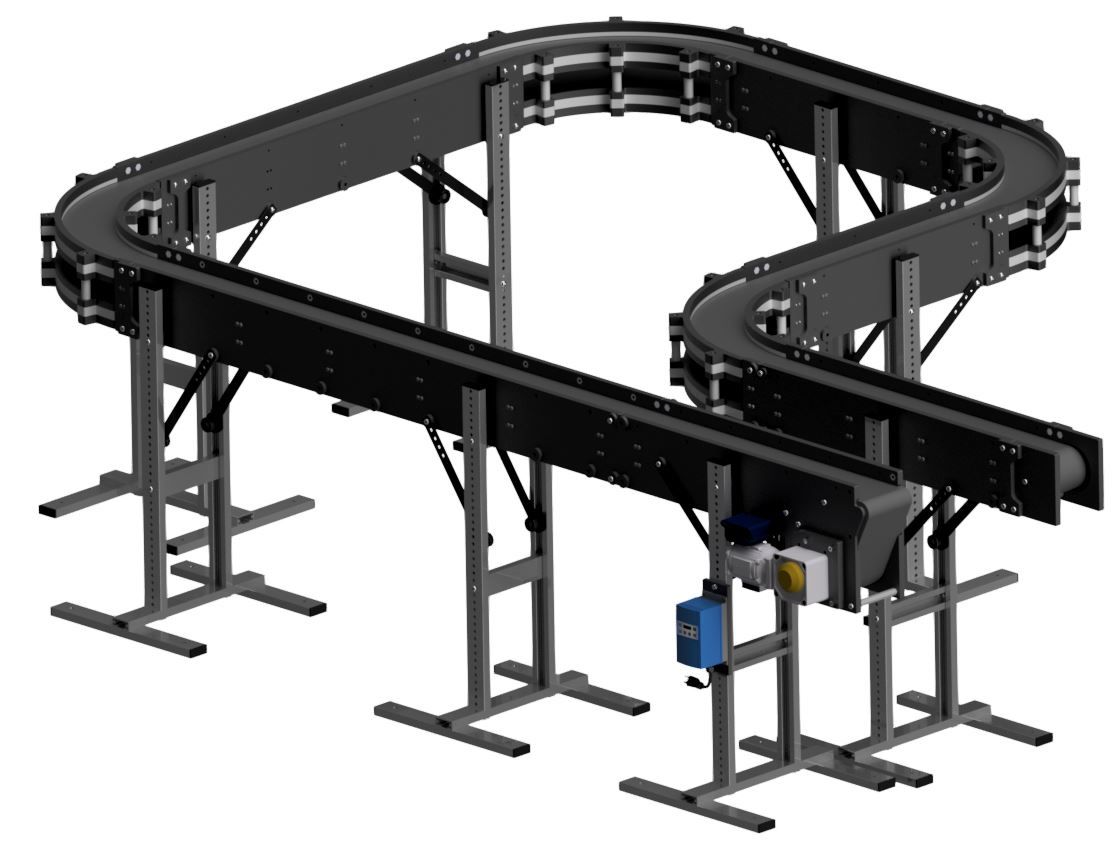

Radius Conveyors

Hybrid radius turn conveyors make the required lateral turns (from 5o to 180o) and connect with other modules to build one conveyor with continuous belt flow.

These are examples of the many possible configurations using Hybrid specialty conveyors

Tight turn radius conveyor

Hybrid over and under air blowoff

Box turning conveyor

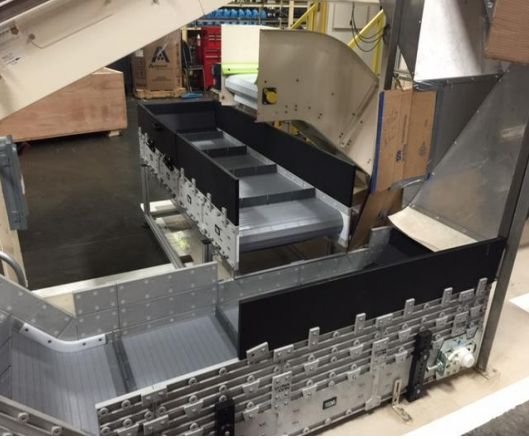

Multi-gaylord filling system

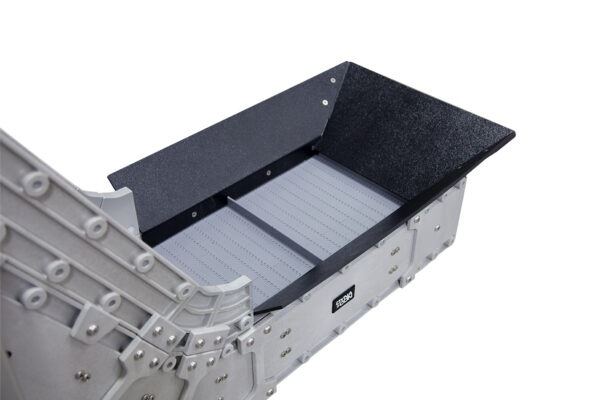

Accessories

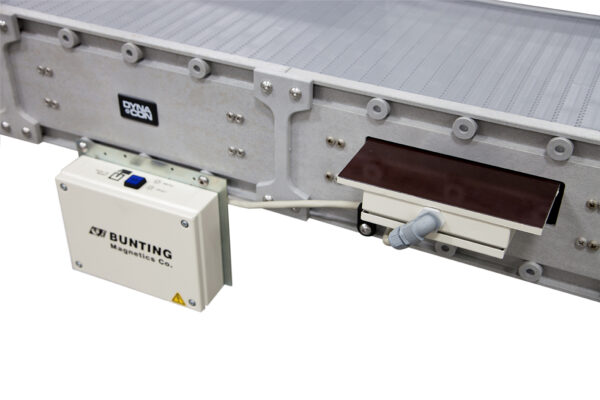

- A variety of options help meet your product’s high standards, including metal detection, ionizers, cooling fans and water bath tanks

- Hybrid conveyors are easily adaptable to meet clean room conveyor requirements

- Chutes, hoppers, diverting arms and parts transferring accessories are available to fit all of your conveying needs

- Accessories like E-Stop and Photo Eye Stop bring added safety and efficiency to your facility

- Case Turning Conveyor options are also available

Features and Benefits of Hybrid Specialty Conveyor Solutions

- Widths from 1 to 120 inches

- Lengths as long as 150 feet

- Various sidewall heights available including flush to belt

- Unlimited angles and geometries to create precise inclines, declines and radius turns

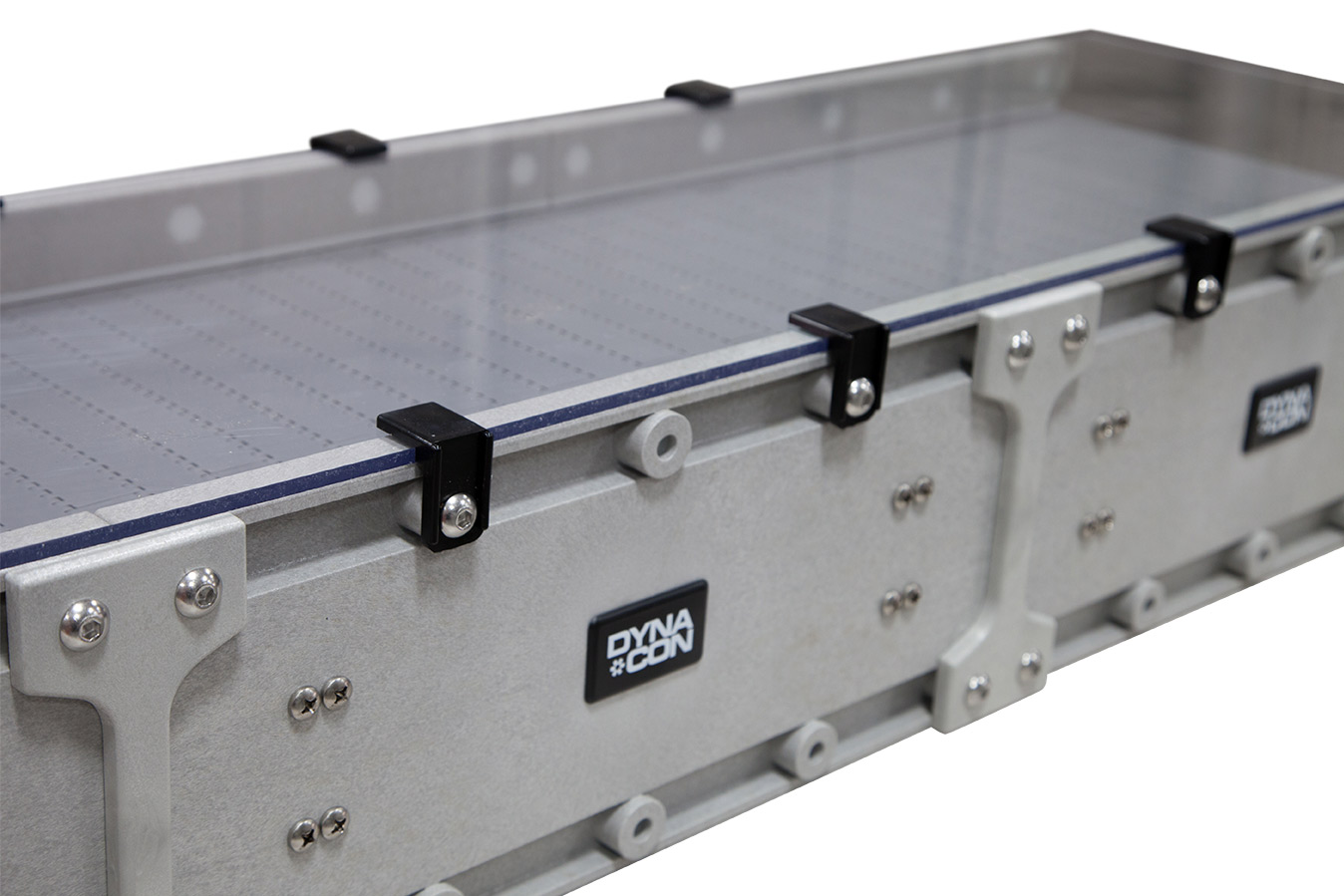

- Self-tracking belts using plastic modular link style belt for improved durability

- An endless number of custom options and accessories

- Designed to seamlessly integrate with your existing equipment

- Eco-friendly motors that are quiet, energy efficient and maintenance-free

- Standard 5 year warranty

ROI

Low Cost of Ownership

Low cost of ownership is a crucial consideration for businesses when making purchasing decisions. It refers to the total cost of owning and operating a product or asset over its lifespan. Low cost of ownership can help to reduce expenses, increase profitability, and promote sustainable and responsible asset management strategy. Achieving a low cost of ownership can be accomplished by selecting high-quality, durable products and implementing efficient maintenance and repair processes. By prioritizing a low cost of ownership, businesses can save money and resources while also contributing to a more sustainable future.

- Modularity: Hybrid conveyors are designed with a modular philosophy allowing them to later be modified to meet specific and changing needs of our customers business, which can help to reduce costs by eliminating need to purchase new equipment in the future.

- Quality Components: We utilize high quality components in all our designs. This leads to a durable conveyor system built to last. Reduces replacement parts costs, maintenance costs, and minimizes spare parts inventory needing to be carried.

- Low Maintenance Costs: The design simplicity of our conveyors minimizes the number of components and wear items in a conveyor, minimizing repairs and preventative maintenance. Additionally, we utilize non-tensioned belts in all our designs eliminating the maintenance time to continuously track belts.

- Energy Efficiency: Standard motor packages include DC brushless motors, with reversing and variable speed capabilities. These motor packages reduce energy consumption by an average of 30% year-over-year relative to a standard 3 phase AC motor package.

- Easy Integration/Installation: Many conveyors can be easily installed and integrated with other equipment, which can help to reduce costs associated with additional onsite fabricators, installers.

Solutions

We’ve Built Conveyors For:

English

English Español

Español Français

Français