Since our inception, we’ve focused on moving the manufacturing industry up to new heights by creating fully integrated material handling conveyor systems for lean manufacturing processes and optimizing floor spaces.

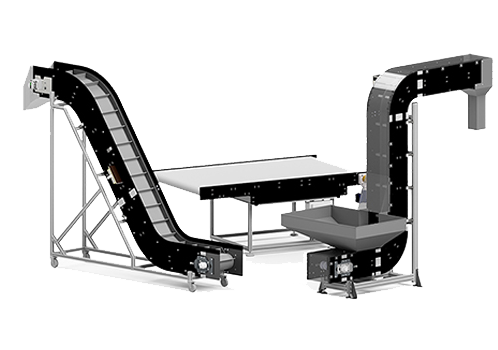

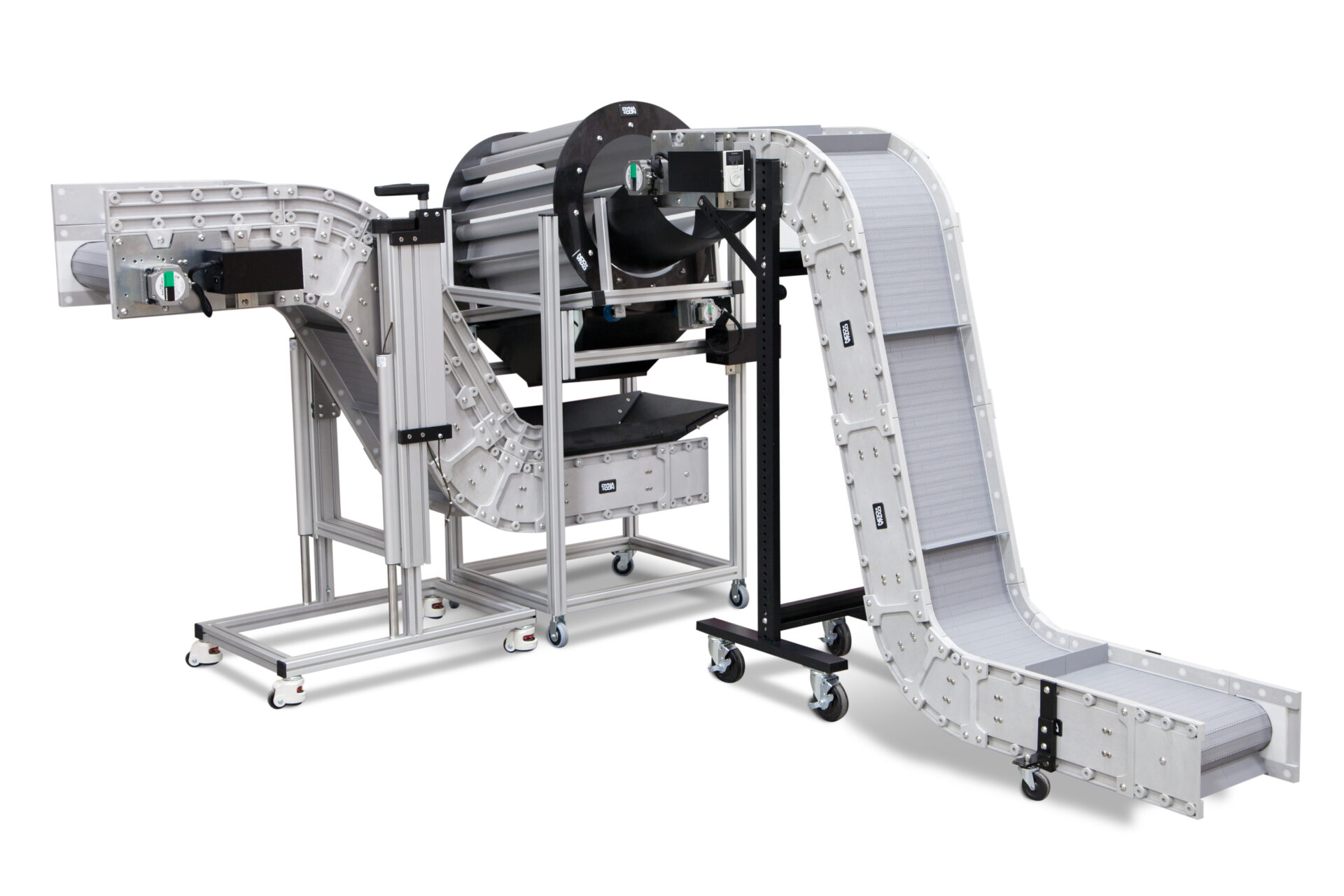

Our custom belt conveyor systems provide maximum flexibility and sustainability at standard conveyor prices. Built using performance plastics, the conveyors are lightweight, require minimal maintenance, and allow you to implement configuration changes to your manufacturing processes with no disruption.

Manufacturing Conveyor Benefits

- Full controls packages and installation services available

- Tensionless belt – conveyor system requires no belt tracking

- Maintenance-free and energy efficient motors

- Shipped economically for reduced costs

- 5 – Year Product warranty included

- Material Handling Conveyor Application Examples: Trunkline conveyors, takeout conveyors, vertical and incline conveyors, and cleanroom conveyor systems

Industries We Serve

- General/Parts Manufacturing

- Plastics Injection & Blow Molding

- Automotive

- Metal Stamping

- Medical Device & Equipment

- Packaging

- Clean Rooms for Manufacturing