https://www.youtube.com/watch?v=CbhghMJuhdQ&autoplay=1

It's time for a new LINE OF THINKING

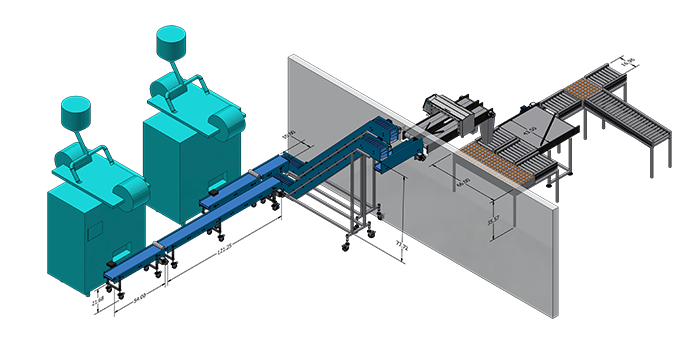

Custom conveyor solutions for those who can't slow down.

Watch The VideoEngineered Conveyor Systems

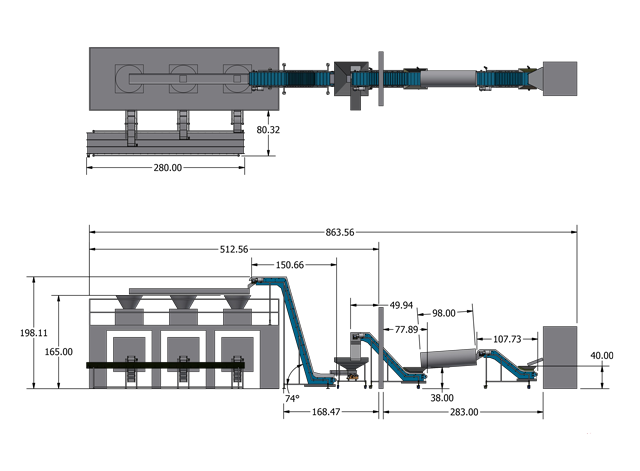

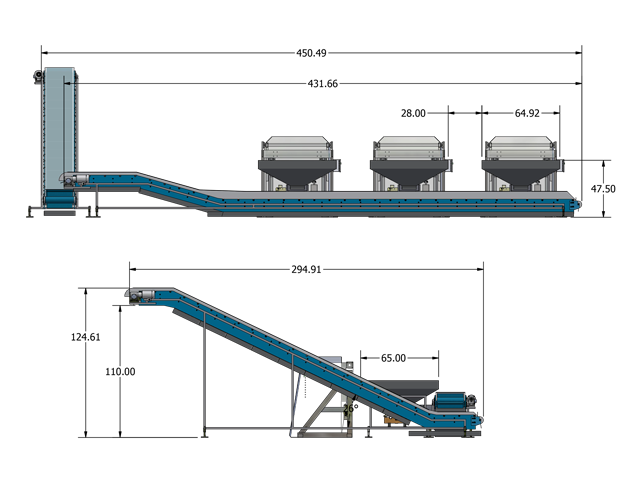

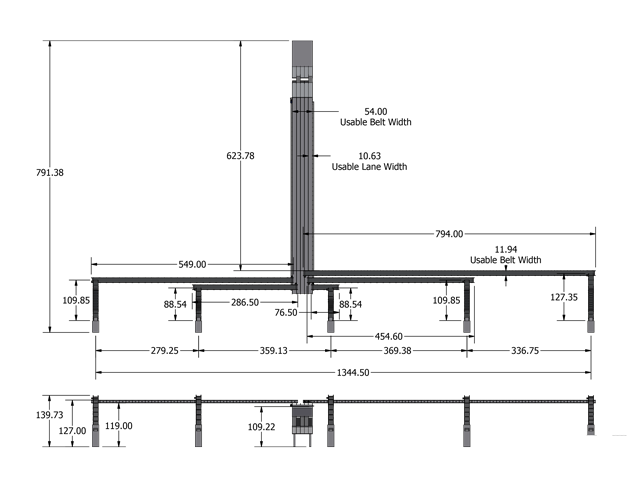

To operate at its best and most efficient, your manufacturing facility needs a variety of conveyor solutions to meet the wide range of applications inside. From production to packaging you need full turnkey automation solutions to streamline your processes and increase efficiencies. Our Engineering Team is ready to meet your facility’s toughest challenges with conveyor systems engineered just for you.

Engineered Systems

What’s New

Building Better Conveyors and Connections: Dynamic Conveyor’s 2025 Year in Review

2025 seemed to mark a turning point in how manufacturers think about conveyors and material handling. Across food, packaging, plastics, and general manufacturing, the conversation…

Read More

What Makes Us Different?

In this video, you will hear about what makes us unique.