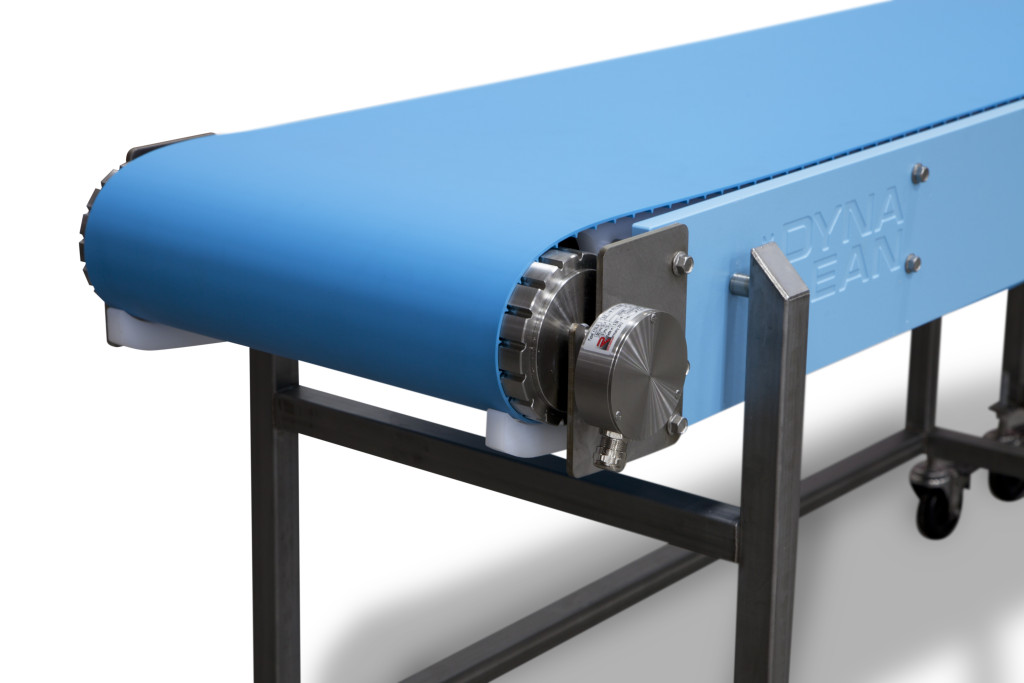

All Food Grade Conveyors Aren’t the Same and Neither is the Belting

Food grade  conveyor belting is a very important part of the sanitary conveyor system; without them, quite simply, your product can’t be conveyed. There are several food grade belt suppliers and styles, but keep in mind that not all belts are equal. The following checklist will help you ask good questions when selecting the right belt for your next food grade conveyor system.

conveyor belting is a very important part of the sanitary conveyor system; without them, quite simply, your product can’t be conveyed. There are several food grade belt suppliers and styles, but keep in mind that not all belts are equal. The following checklist will help you ask good questions when selecting the right belt for your next food grade conveyor system.

Tensioned versus non-tensioned food grade conveyor belting

For the best access to the frame and internal components of the conveyor, choose a conveyor system that includes a belt that doesn’t require any pre-tension. Tensionless food grade belting fits loosely and allows you to lift the belt for full access to the inside of the conveyor system. Easy access to the internal components allows the conveyor to be thoroughly cleaned in place (CIP), reducing the risk of harboring harmful bacteria.

Look for belts that are self-tracking. Sprocket-driven positive tracking systems eliminate mis-tracking issues and potential damage to the belt.

Food products come in all kinds of shapes and sizes and may be sticky, oily, greasy, wet, frozen or steamy hot. The form and temperature plays a critical role in the proper selection of belt type and style.

All blue belts are not the same

Blue food grade conveyor belting is popular in food processing plants because of its color. The blue color makes it much easier to identify soil impurities. There are blue homogenous solid surface plastic belts and those that contain reinforcing fibers. When non-homogeneous belts with reinforcing cords or fabric are damaged or worn, the reinforcements become exposed and can absorb fluids and harbor bacteria. What results is a source of contamination that is often difficult to detect and impossible to clean. Belts made from layers of different materials like fabric and plastic may have the layers come apart, exposing the fabric and causing sanitation problems. Using a belt that is made from only one material eliminates these risks. There are many food grade conveyor belts that are blue in color, but remember they aren’t all homogenous.

Modula r plastic belting

r plastic belting

Choose modular plastic link style food grade conveyor belting when durability, cold or very warm temperatures are required. Modular plastic offers maximum sanitation, as well as corrosion and abrasion resistance and customization opportunities. Modular plastic belting can be molded in materials that allow conveyance of product as cold as -50o F or as warm as 200o F. Belting styles include nub top, flush grid and a variety of drive flight options to create a belt to meet most every food application need.

Metal mesh belting

When there is a need to batter, bread, glaze, coat, cool, drain, dry or wash product then metal mesh food grade conveyor belting is the answer. Metal mesh belting is also transparent, metal detectable and allows for tight transfers which aids in the gentle transfer of small or delicate products.

No matter your food processing application, you want to look for a belt that will keep your maintenance costs at a minimum and your food product safe.

Stay informed by Subscribing to our E-News

- Celebrating Freedom, Teamwork, and a Month of Success - July 7, 2025

- Mechanical_Design Engineer - June 18, 2025

- Driving the Future of Manufacturing: Dynamic Conveyor at the Beyond Boundaries Automation Event - June 17, 2025