Authored by: Matt Zehr, Manager, Applications & Product Development Engineering at Dynamic Conveyor Corporation

In manufacturing operations and conveyor systems, motors are the unsung heroes. They drive productivity, ensure smooth operation, and—when chosen wisely—can significantly reduce energy costs and maintenance downtime. But not all motors are created equal. Understanding the differences between motor types and their efficiencies can guide smarter operations.

The types of motors selected for conveyors have a significant impact on performance, energy efficiency, and long-term operational costs. In this article, we’ll break down the key differences between common motor types—AC induction, DC brushless, and servo motors—highlight why motor efficiency matters, and explain why utility companies reward energy-smart choices. Whether you’re searching out a new conveyor system or upgrading an existing one, understanding these fundamentals will help you understand the value of motor selections for conveyors.

Types of Motors Used by Dynamic Conveyor

1. AC Induction Motors

- Pros: Simple, cost-effective, reliable, and widely available.

- Cons: Run hot (up to 160°F internally), heavier, and less efficient. Read more about Temperature Rise and Heat Resistant Class of AC Motor

- Applications: Industrial machinery, HVAC systems, conveyors, conveyor drives that require more than 200 Watts, irrigation pumps, heat pumps, etc.

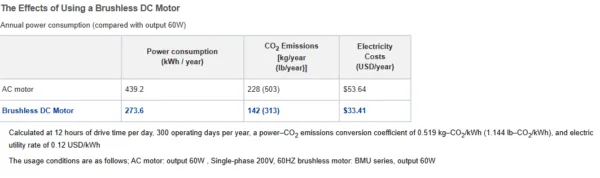

2. DC Brushless Motors

- Pros: Highly efficient, lightweight, cooler operation, flat torque curve over wide range of speed.

- Definition: Torque control in conveyance refers to the ability to precisely manage the amount of rotational force (torque) that a motor applies to a conveyor system. This is crucial for ensuring smooth, efficient, and safe operation, especially in systems that handle varying loads or require precise movement.

- Cons: Limited size and voltage options; typically, fractional horsepower.

- Applications: Robotics, automation equipment, electric vehicles, power tools, and conveyors when conveyor drives require less than 200 watts.

Learn more about how motors contribute to energy savings using this Oriental Motors Guide to Carbon Neutrality: Getting Started

3. Servo Motors

- Pros: Exceptional precision, high torque and speed, closed-loop feedback for accurate positioning.

- Cons: Higher cost and complexity.

- Applications: High-precision automation applications such as robotics and certain conveyance systems that require exact placement using positioning devices and/or high speed divert.

Efficiency Matters: Why It’s More Than Just Energy Savings

Motor efficiency directly affects:

- Energy consumption: High-efficiency motors use less power, reducing operational costs.

- Heat generation: Cooler motors last longer and reduce the need for additional cooling systems.

- Torque and speed control: Efficient motors maintain torque across a wider speed range, improving performance.

- Size and weight: Efficient motors can deliver the same power in a smaller footprint.

For example, a DC brushless motor can be half the size of an AC motor while delivering the same output—saving space, allowing for easier machine integration as well as saving energy.

Control Methods and Performance

- AC Motors: Speed is controlled via frequency (typically with a Variable Frequency Drive or VFD), deviating under 20HZ and over 60 HZ reduces torque and efficiency.

- DC Brushless Motors: Use electronic feedback for precise control. They use a motor driver for control and maintain torque across a wide speed range (e.g., 50–4,000 RPM).

- Servo Motors: Use a servo drive to compare feedback from the motor (e.g., actual position or speed) to the commanded value and adjust power to the motor to minimize any error. This closed-loop control is what gives servo systems their precision and responsiveness.

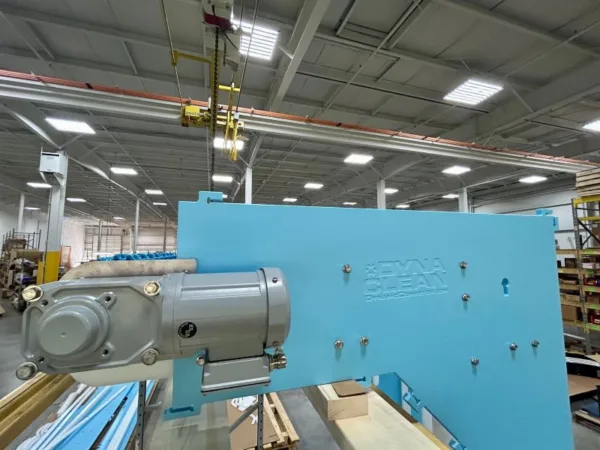

Real-World Impact: A Customer Success Story

Dynamic Conveyor’s choice of motor on conveyors designed for Robinson Manufacturing allowed the customer to realize that their conveyor loads didn’t require oversized motors. High-efficiency DC brushless motors, reduced energy consumption and overall cost of ownership—without sacrificing performance. Read the Customer Success Story

Other Considerations

- Backdriving: Brakes should be used when there is potential for back driving load on incline conveyors.

- IP Ratings: For washdown or cleanroom environments, motors must meet specific IP (Ingress Protection) standards to prevent contamination or damage.

- Thermal Protection: Some motors include thermal overload sensors to prevent overheating and damage.

Utility Incentives for High-Efficiency Motors

Did you know that many utility companies across the U.S. offer rebates and financial incentives to encourage businesses to use and upgrade to high-efficiency motors and drives? These programs help reduce overall energy demand on the grid, especially during peak times, and support sustainability goals. Motors that meet or exceed NEMA Premium® efficiency standards, as well as systems using DC brushless or servo motors with variable frequency drives (VFDs), often qualify for these incentives.

To take advantage, businesses should consult their local utility provider or energy efficiency program. The savings can be substantial – rebates can offset initial upgrade costs, and the improved energy efficiency often leads to a fast return on investment through lower operating expenses.

Final Thoughts: The Right Conveyor Motor Matters

Choosing the right motor for your conveyor system isn’t just about power – it’s about efficiency, control, and long-term value. Whether designing a new conveyor system or upgrading an existing one, understanding motor technology can lead to smarter, more sustainable decisions.

Our experienced engineering team is here to design a conveyor system with the components like motors that best fit your application. Contact Us today to start the customer conveyor design process.