In the fast-paced world of manufacturing, efficiency is key. Every second counts, and companies are constantly seeking ways to streamline their processes and enhance productivity. One often overlooked but crucial element in this quest for efficiency is the role of conveyor accessories. These small components contribute to enhancing the performance of conveyor systems, thus contributing to increased productivity, product quality and worker safety.

1. Controls and Automation:

Conveyor accessories, such as sensors and automation systems, bring a new level of precision to manufacturing processes. Automated conveyor systems equipped with sensors can detect and sort items based on size, weight, or other criteria, reducing, or eliminating the need for manual intervention. This not only speeds up the production line but also minimizes errors, leading to more efficient and reliable operation. Integrating conveyors with other auxiliary machinery streamlines production, reducing manual labor and minimizing the margin for error. This integration leads to increased output capacity and faster production cycles, allowing manufacturers to meet growing demands with ease.

Furthermore, machinery integration facilitates the implementation of advanced technologies such as robotics, artificial intelligence, and the Internet of Things (IoT). These technologies enable real-time monitoring, data analysis, and predictive maintenance, ensuring optimal performance and minimizing downtime. Automation enhances workplace safety by handling repetitive or hazardous tasks, allowing human workers to focus on more complex and strategic aspects of production. Dynamic Conveyor has experienced Controls Engineers on staff to set up conveyor controls and integrations with existing equipment and machinery.

2. Conveyor Sorting, Diverting & Separation Systems:

Conveyor accessories designed for sorting and diverting products, packages and parcels are a key factor in delivering different items efficiently. With the ability to divert products to different lanes or stations based on predetermined criteria, these systems enhance the speed and accuracy of the production process. This is particularly beneficial in industries where customized or varied product specifications are common. Conveyor Parts separators enhance the efficiency and precision of the manufacturing process. These specialized tools are designed to separate and organize components during various stages of production, ensuring a seamless workflow. Parts separators reduce the risk of errors and defects by preventing mix-ups and misplacements, which can be particularly critical in industries where precision is paramount. Parts separation systems also contribute to increased productivity by streamlining the assembly line and minimizing downtime associated with manual sorting.

These accessories facilitate better quality control, allowing manufacturers to maintain higher standards and meet stringent specifications. In packaging and parcel applications these accessories prevent bottlenecks, enhance speed and accuracy and overall efficiency.

3. Metal Detection:

One of the primary reasons why metal detection is a beneficial conveyor accessory is its ability to prevent contamination in the production process. In industries such as food processing and pharmaceuticals, where product quality and safety are paramount, the presence of metal contaminants can lead to serious consequences. Metal detectors integrated into conveyors can swiftly identify and remove unwanted metal objects, ensuring that the final product meets stringent quality standards.

In other industries, metal detection helps protect expensive downstream equipment from damage caused by metal fragments, reducing downtime and maintenance costs. Implementing metal detection technology in conveyor systems safeguards the integrity of the conveyed products and contributes significantly to operational reliability and product quality assurance. Check out these examples: 1) Metal Detection on a DynaCon Conveyor 2) Metal Detection with Reject Chute on a DynaClean Food Conveyor.

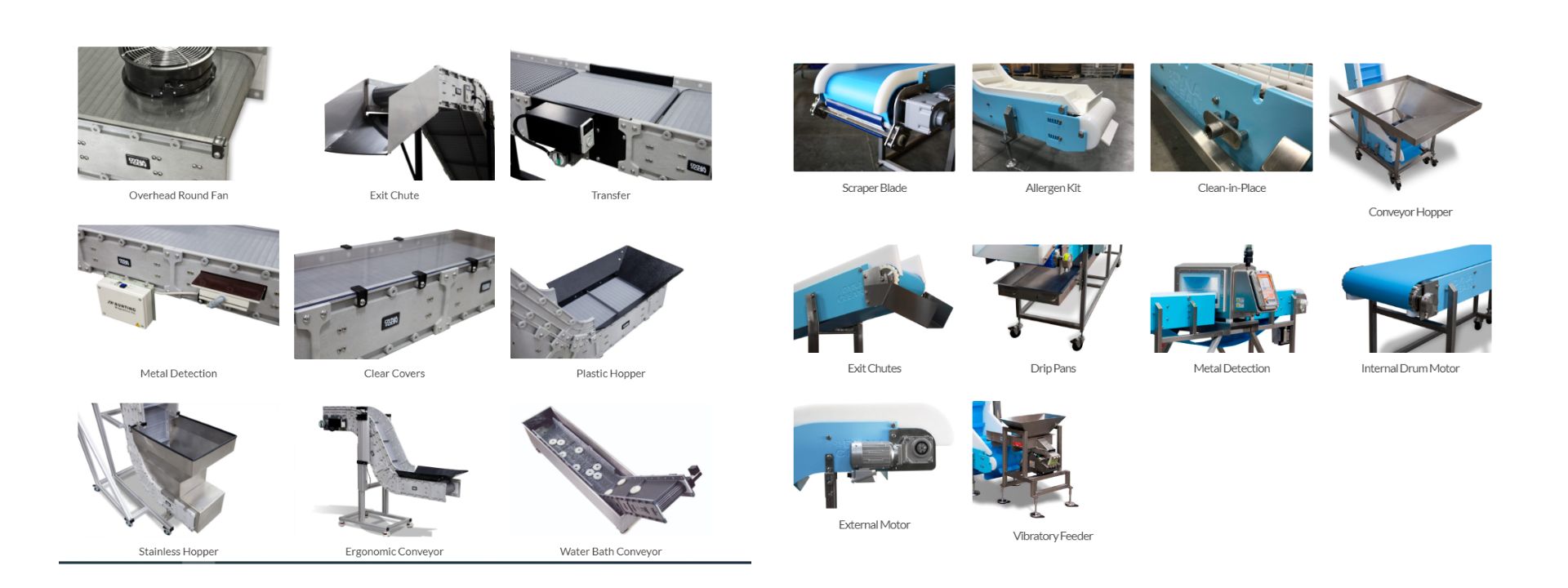

4. Hoppers, Vibratory Feeders & Chutes:

Hoppers, vibratory feeders, and chutes serve as invaluable accessories for conveyors due to their pivotal role in material handling and transfer processes. Functioning as reservoirs or containers, these accessories efficiently collect, store, dispense and regulate the flow of bulk materials before introducing them onto the conveyor belt. This not only optimizes the feeding process but also facilitates a consistent and controlled material supply, preventing potential disruptions or irregularities in the conveyor system.

These accessories contribute to enhanced efficiency by reducing the risk of material spillage and ensuring a steady, measured input onto the conveyor. Moreover, they enable the accommodation of varying material volumes, aiding in the seamless handling of diverse materials. Conveyor hoppers, vibratory feeders & chutes play a crucial role in streamlining conveyor operations, promoting reliability, and supporting a smoother workflow in manufacturing. Check out the examples below:

5. Covers and Catch Pans:

Clear covers for conveyors offer several benefits in industrial settings. Firstly, they provide visibility into the conveyor operation, allowing operators to monitor the material flow, identify potential issues, and conduct inspections without the need to open or dismantle the system. This transparency enhances overall system control and troubleshooting efficiency. Additionally, clear covers protect the conveyed materials from external elements such as dust, debris, and moisture, preventing contamination and maintaining product quality.

The covers also contribute to a safer working environment by containing materials within the conveyor system, reducing the risk of spillage, and minimizing the potential for accidents. Furthermore, clear conveyor covers can serve as a safety feature by preventing unauthorized access to moving conveyor parts. Overall, the use of clear covers enhances operational visibility, safeguards product integrity, and promotes a safer and more controlled conveyor environment.

Catch pans play a crucial role in maintaining the cleanliness, safety, and efficiency of conveyor systems. These pans are strategically positioned beneath conveyors to catch and contain any material spillage or debris that may occur during the conveying process. By preventing materials from falling onto the surrounding area, catch pans help create a safer working environment, reducing the risk of slips, trips, and falls. Moreover, they contribute to the preservation of valuable materials by minimizing waste and facilitating easy cleanup. Catch pans also aid in complying with environmental regulations by preventing contaminants from entering the surroundings. Beyond safety and environmental benefits, catch pans enhance the overall efficiency of conveyor systems by minimizing downtime associated with cleanup and maintenance. In summary, catch pans are integral conveyor accessories that promote safety, environmental responsibility, and operational efficiency in various industrial settings.

6. Part Conditioning

Part conditioning accessories including cooling, water dredging, cleaning, air filters, and ionizing enhance the manufacturing process by ensuring the optimal performance and longevity of components and machinery. A notable benefit is the ability to control and maintain the temperature of conveyors and other manufacturing equipment, preventing overheating, and minimizing thermal stress on parts. This reduces maintenance costs and enhances the reliability of the entire production line. Some of the most popular part conditioning accessories for conveyors include:

- Ionizers

- Air filters

- Cooling fans

- Water bath tanks

These conditioning accessories contribute to the smooth operation of manufacturing processes by regulating temperature, removing contaminants, and preventing issues related to heat and static electricity. Their integration enhances overall efficiency, reduces downtime, and improves the quality and reliability of manufactured goods.

7. Byproduct Containment

Managing and containing the byproducts of a primary manufacturing process is a key contributor to environmental protection, health and safety, regulatory compliance, resource recovery, and corporate responsibility. But it also has an indirect impact on productivity. Proper byproduct containment systems for conveyors enhance overall operational efficiency by reducing the risk of unplanned shutdowns and interruptions presented by spills, and other environmental incidents that could halt production.

Byproduct containment accessories vary depending on the nature of the byproducts and could range from drip trays to storage tanks. Conveyor byproduct containment accessories will mitigate environmental impacts, protect human health, comply with regulations, and promote responsible and sustainable business practices. When scoping conveyor projects, Dynamic Conveyor will ask about byproducts and make recommendations for respective containment options.

Conveyor Accessories for Modern Manufacturing Operations

In modern manufacturing the impact of conveyor accessories on productivity cannot be overstated. From automation and precision to cleanliness and adaptability, these components play a pivotal role in optimizing conveyor systems and other equipment. As industries continue to evolve, embracing the latest advancements in conveyor accessories will be essential for staying ahead of the curve and achieving higher levels of productivity, efficiency, and safety. Manufacturers who recognize the value of these small components are poised to reap the benefits of a well-orchestrated and high-performing production line.

Dynamic Conveyor engineers and builds custom conveyors to meet the unique needs of each manufacturer. Designed systems come with these and a variety of other important conveyor accessories to assist manufacturers in achieving operational excellence and increased productivity. Contact us for a new line of thinking about conveyors in your operation.

Request More Information

Ready to take your productivity to the next level? Complete the form below for more information, or to get a quote for your custom conveyor solution.

- Celebrating Freedom, Teamwork, and a Month of Success - July 7, 2025

- Mechanical_Design Engineer - June 18, 2025

- Driving the Future of Manufacturing: Dynamic Conveyor at the Beyond Boundaries Automation Event - June 17, 2025