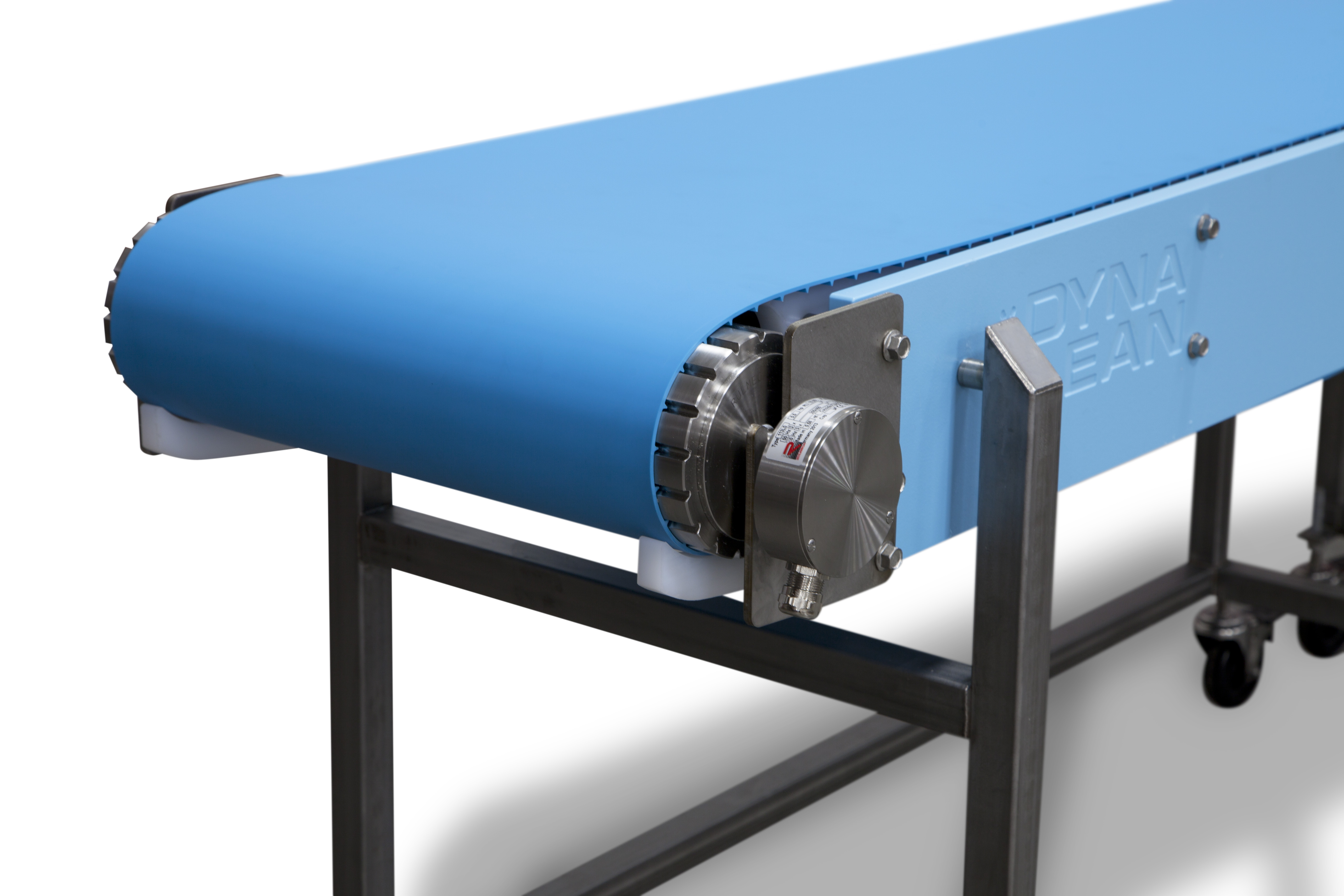

A drum motor is a one component of the conveyor drive where the motor, gear drive and all moving parts are enclosed inside the drum. The motor and gears operate in a sealed oil bath ensuring proper lubrication and cooling. With no external motor, gear reducer, sprockets, chain or OSHA required chain guard, no external component maintenance is required. Because of these features, sanitary drum motors are an ideal drive motor option for conveyor systems in the processing zone and raw-food handling areas of food plants.

A drum motor is a one component of the conveyor drive where the motor, gear drive and all moving parts are enclosed inside the drum. The motor and gears operate in a sealed oil bath ensuring proper lubrication and cooling. With no external motor, gear reducer, sprockets, chain or OSHA required chain guard, no external component maintenance is required. Because of these features, sanitary drum motors are an ideal drive motor option for conveyor systems in the processing zone and raw-food handling areas of food plants.

Benefits of Sanitary Conveyor Drum Motors:

- Hermetically sealed and totally enclosed design is corrosion resistant

- The drum motor can be removed from the sanitary conveyor within seconds without the use of tools

- Easy to clean without the need to remove sprockets, which reduces the risk of contamination

- Stainless steel construction with lagged roller is safe and easy to clean

- No externally mounted bearings to clean, sanitize or maintain

- No external moving parts increases operator safety

- Compact single unit design enhances space utilization

- IP 67 rated for high pressure wash down and protection against occasional submersion

- Uses up to 32% less energy than standard food conveyor motors

Utilizing a sanitary drum motor will eliminate the opportunity for food byproducts to get trapped, decreasing the potential for bacterial contamination. This considerably decreases cleaning time and labor costs. Drum motors can be cleaned and sanitized to an optimal level in less than half the time it takes to clean a typical geared motor.

Hygienic, sealed for life, maintenance-free and space savings give good cause for considering a sanitary drum motor on your next food processing conveyor.

Download Our Sanitary Conveyor Cleaning Recommendations

- Mechanical_Design Engineer - June 18, 2025

- Driving the Future of Manufacturing: Dynamic Conveyor at the Beyond Boundaries Automation Event - June 17, 2025

- Overhead Conveyors: Boosting Efficiency in Manufacturing - June 13, 2025