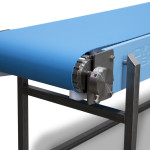

External gear motors and internal drum motors are the two basic options food processing companies have for driving their belt conveyors. Choosing the motor type is a necessary part of selecting a food grade conveyor system. Traditionally, food processing conveyors have included external gear motors as the belt-drive mechanism, but internal drum motors are an alternative that food processors should take a look at.

External gear motors and internal drum motors are the two basic options food processing companies have for driving their belt conveyors. Choosing the motor type is a necessary part of selecting a food grade conveyor system. Traditionally, food processing conveyors have included external gear motors as the belt-drive mechanism, but internal drum motors are an alternative that food processors should take a look at.

Because of the hygienic benefits, internal drum motors are becoming the drive technology of choice in the processing zone and raw-food handling areas of food plants. Gear motors are perceived as being more cost-efficient. Up front, many gear motors do cost less than drum motors, but with drum motors being more hygienic, easy-to-clean, maintenance-free and compact, they actually save companies money in the long run.

Internal drum motors clearly provide superior sanitary design. Risk of soil accumulation and cross-contamination is significantly lower for drum motors than for gear motors. The roller is used to drive the belt on the conveyor without the need for sprockets. With external gear motors, food byproducts may accumulate in the areas between the sprockets, shaft, keyway, external bearing and retaining clips. Utilizing a drum motor will eliminate the opportunity for food byproducts to get trapped, decreasing the potential for bacterial contamination. This considerably decreases cleaning time and cost for conveyor operators. Drum motors can be cleaned and sanitized to an optimal level in less than half the time it takes to clean a typical geared motor.

In addition to hygienic design, drum motors have other clear advantages as well. Ease of installation and maintenance along with the ability to fit into restricted spaces are among the benefits of using conveyor drum motors. Drum motors are compact and offer advantages for installation, making them the only possible choice in some layouts. Traditional gear motors extend beyond the belt with chains, pulley and guarding. This adds to the risk of exposure and also reduces the number of conveyors that can be installed in a food processing plant. With motor, bearings and gearbox enclosed inside the drum casing, drum motors offer a streamlined design that fits within the confines of the conveyor system to maximize space. Drum motors use fewer components which means installation is simpler and faster than that for gear motors.

Drum motors feature a stainless steel drum casing with all the subcomponents embedded inside. The totally enclosed and hermetically sealed design ensures that internal parts are not exposed to external environmental conditions or tampering. Internal drum motors are a completely self-contained unit and require no maintenance throughout the lifetime of the conveyor system.

Hygienic, sealed for life, maintenance-free and space savings give good cause for considering a drum motor on your next food processing conveyor.

Subscribe to our E-News and stay informed!

- Celebrating Freedom, Teamwork, and a Month of Success - July 7, 2025

- Mechanical_Design Engineer - June 18, 2025

- Driving the Future of Manufacturing: Dynamic Conveyor at the Beyond Boundaries Automation Event - June 17, 2025