When ordering an incline conveyor, the conveyor manufacturer will ask you some basic questions that will need to be answered. Basic information like the length and width are usually straight forward and easy to answer. Often, both parties forget to exchange more detailed information.

When ordering an incline conveyor, the conveyor manufacturer will ask you some basic questions that will need to be answered. Basic information like the length and width are usually straight forward and easy to answer. Often, both parties forget to exchange more detailed information.

In the rush of ordering an incline conveyor, sometimes the pertinent questions are glossed over or entirely forgotten. Ignoring the details can result in a conveyor that is not capable of conveying your parts efficiently and damage free.

The most important conveyor component to specify correctly is the conveyor belt. In order to get the correct belt on your conveyor system, you will want to give the conveyor manufacturer as much information about the parts that you will be conveying on the conveyor. Sending product samples or even sharing a CAD drawing or picture of the product is extremely helpful. The conveyor manufacturer has the experience of looking at a part and determining if there is anything about it that will make it difficult to convey.

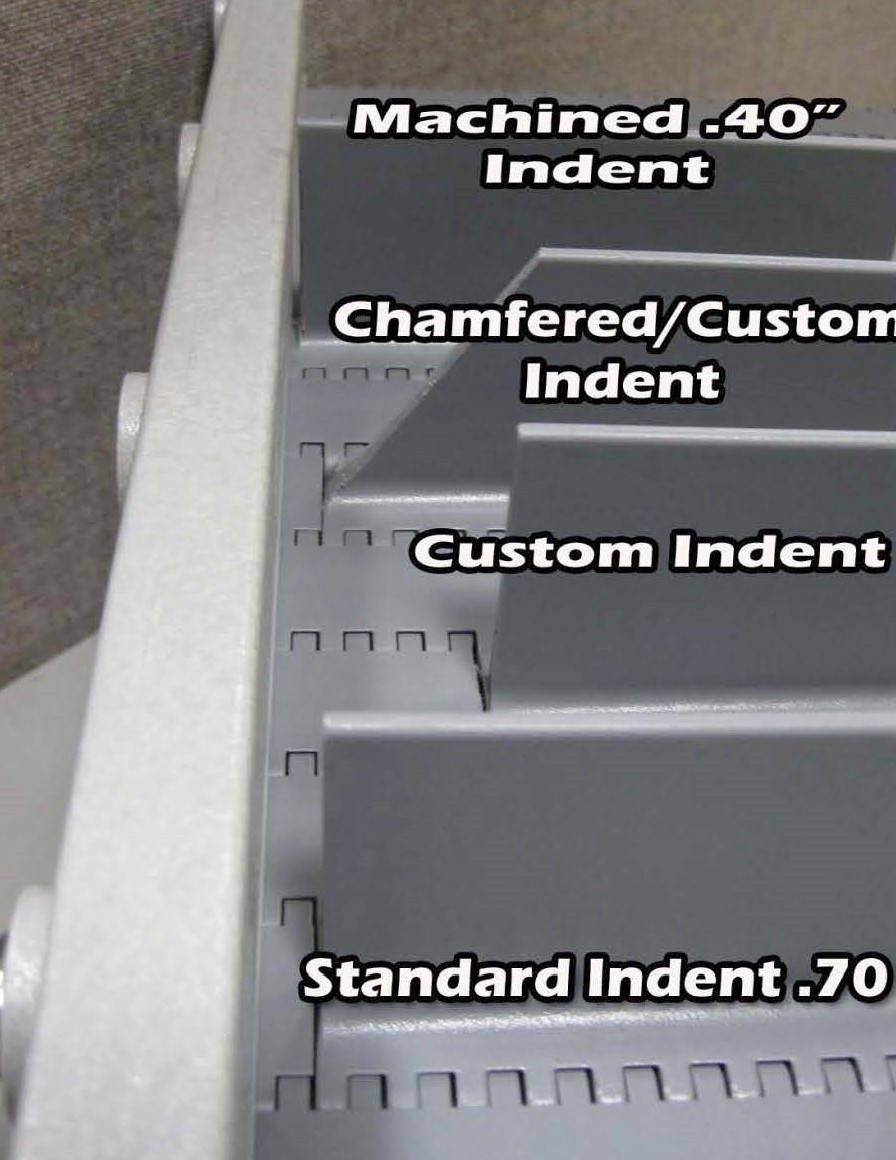

Sometimes a relatively large part has a small feature (think of a plastic syringe) that can get pinched between the sidewall of the conveyor and the belt drive flights. The pinching most likely will cause damage to your product. In this case, product damage can be eliminated by changing the standard indent (the distance between the side of the conveyor and drive flight) to a custom drive flight indent. The distance is decreased, so the drive flight almost touches the sidewall, eliminating the chance of your parts getting stuck.

Conversely, the indent can be increased to allow your parts to fall past the sidewall with no possibility of getting wedged. Additionally, the ends of the drive flights can be chamfered to any angle. This angle allows the part to ride up the moving drive flight and moves the part away from the sidewall, preventing product damage.

If all of your product information is shared on the front end, with an experienced conveyor manufacturer, you can be assured that when ordering an incline conveyor, you will get a conveyor system that will meet or exceed your expectations.

Want a conveyor that doesn’t damage your parts? Get a Quote

- Buy a Conveyor or Not: When is it Time to Buy a Conveyor? - December 6, 2022

- Dynamic Conveyor Introduces New Modular, Powered Roller Conveyor for End of Line Solution in Manufacturing - May 20, 2022

- How to Reduce Conveyor Maintenance Costs - September 30, 2020