Crest Foods is a third-generation contract packaging company with a comprehensive range of dry foods product packaging based in Ashton, Illinois.

Gaining the confidence of today’s buyers of complex capital equipment requires trust. Demonstrating engineering expertise through first engagements and relevant solutions prove crucial to Dynamic Conveyors ability to build trust with new and existing customers.

Designing an Integrated Conveyance Solution with Other Capital Equipment Vendors

Rick Rice, Controls Engineer at Crest Foods, learned firsthand of the engineering expertise of the Dynamic Conveyor team when he was tasked by two partnering businesses to provide an integrated conveyance solution to handle the production and packaging of its cereal line. Rice, an experienced Controls Engineer in food packaging, was introduced to Dynamic Conveyor, its applications engineering team, and the company’s design process. Through the entire scope discovery, design and proposal process Rice was impressed with the Dynamic Conveyor’s processes and engineering expertise that built the foundation for a long-term partnership.

Dynamic Conveyor’s partnership network with other capital equipment manufacturers allows for providing turnkey integrated solutions and builds trust for Crest Foods as well as other new buyers.

Engineering Expertise Leads to New Opportunities

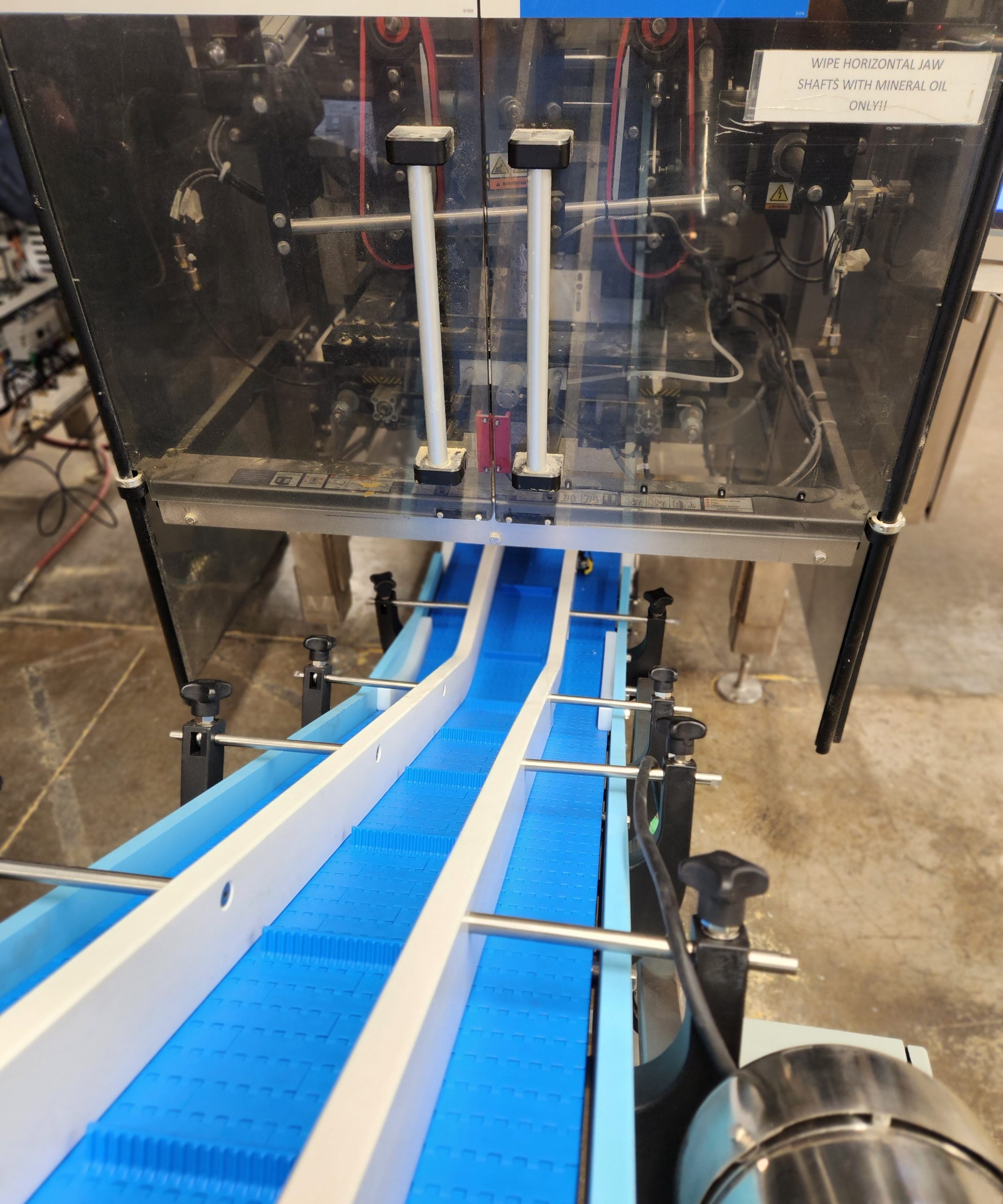

The relationship between the two client companies of Crest Foods delayed the initial integrated system project. However, Crest Foods’ confidence in the engineering talent of Dynamic Conveyor led to other opportunities within their operations for the DynaClean product line, a full washdown sanitary conveyor with toolless disassembly. The new project application was moving blended dry ingredients from a blender, to form fill to cartoner, then to case packer and palletizer. The integration of all these systems needed to be seamless.

The engagement and collaboration between Rice at Crest Foods and the Engineering team at Dynamic Conveyor produced an excellent outcome for the co-packer.

Dynamic Conveyor’s new line of thinking in expanding its applications and controls engineering services has added additional value to buyers of capital equipment and positions the company to meet the growing needs of manufacturing segments including but not limited to food, who are driven by automation.

If you’re seeking a conveyor manufacturer that will integrate their systems with your other capital equipment vendors, request a quote today for more information.

- Mechanical_Design Engineer - June 18, 2025

- Driving the Future of Manufacturing: Dynamic Conveyor at the Beyond Boundaries Automation Event - June 17, 2025

- Overhead Conveyors: Boosting Efficiency in Manufacturing - June 13, 2025