From sticky food products to tight factory footprints to fast-moving fulfillment lines, we at Dynamic Conveyor understand the unique challenges that manufacturers face. At Pack Expo Las Vegas 2025 (Booth SU-28016), we will showcase innovative conveying systems that tackle these everyday pain points with flexible, easy-to-clean, and reconfigurable solutions.

Dynamic Conveyor’s exhibit will highlight systems from its DynaClean® , DynaCon® and Hybrid product lines—each designed to help manufacturers improve uptime, simplify sanitation, and adapt to changing production needs without complex rebuilds or long lead times.

Less Time Cleaning – More Time Producing

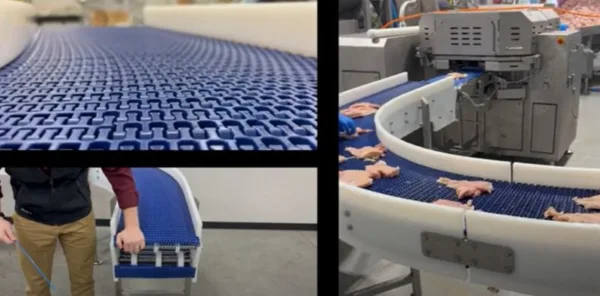

Food manufacturers know that cleanliness isn’t negotiable—but too often, sanitation equals downtime. That’s where the DynaClean conveyor system stands out. Engineered specifically for food environments, DynaClean offers patented toolless disassembly that allows teams to completely take apart and reassemble conveyors in just minutes.

With corrosion-resistant materials like HDPE, UHMW, and stainless steel, DynaClean systems are built to withstand repeated high-pressure washdowns while avoiding common maintenance issues like belt tracking or material degradation. The system’s tensionless belt design, plug-and-play drives, and customizable belting options make it a go-to solution for processors who need hygiene without the hassle.

New for 2025: DynaClean Radius Turn Conveyor Configuration

Navigating tight factory layouts can be a logistical puzzle—but the new DynaClean radius turn conveyor configuration makes it simple. This curved food-grade system is designed to maintain product orientation while changing direction, helping processors preserve spacing, reduce manual handling, and streamline flow—all within a compact footprint.

Like all DynaClean systems, the radius turn is modular, hygienic, and built to connect seamlessly with upstream or downstream equipment.

Vertical Transport, Clean Design

Dynamic Conveyor will also showcase its popular DynaClean Z and S Series conveyors, built to handle both vertical and horizontal transport needs. The Z configuration, in particular, is designed for applications requiring steep inclines up to 25 feet—ideal for processors looking to maximize vertical space without sacrificing cleanability.

Explore Reaching New Heights in Food Manufacturing

Also on display: a wire belted horizontal conveyor, purpose-built for commercial baking environments where full washdown and stainless-steel belting are critical. It’s a demonstration of just how far DynaClean can flex to meet the needs of food manufacturers across categories.

Smart Transfers Made Simple: Right Angle ARB Conveyor

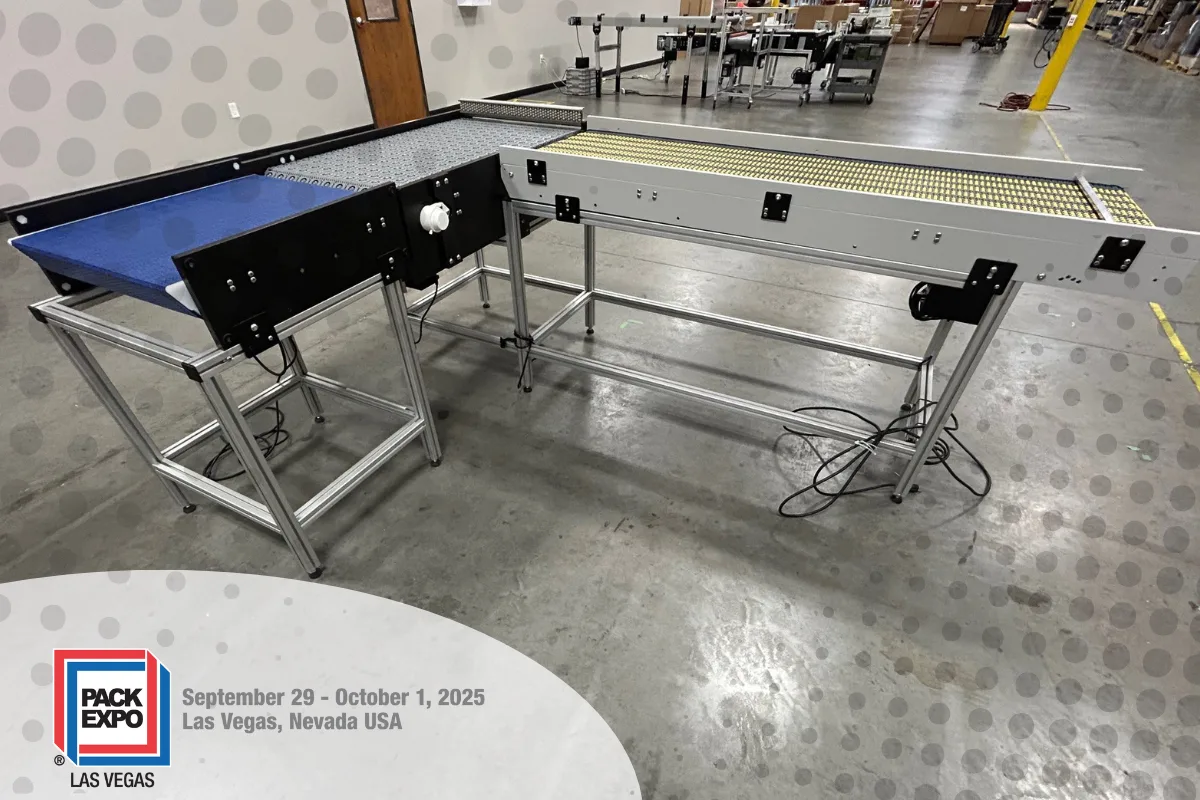

Beyond food, Dynamic Conveyor will feature its Hybrid right angle ARB (Activated Roller Belt) conveyor, a solution designed to bring automation-friendly flexibility to packaging and distribution environments.

Perfect for pick-and-place, end-of-line, and material handling operations, this ARB system transfers boxes 90 degrees without the need for pushers or complex controls. Just the ARB belt and a backstop—keeping it simple, reliable, and adaptable. Whether you’re working in e-commerce, CPG, postal, or automotive, this technology allows for creative, compact layouts that don’t compromise performance.

Modular by Design – Efficient by Nature

Also featured is the DynaCon Z Conveyor, representing the broader value of the DynaCon product line: true modularity. Built with lightweight, durable polycarbonate and aluminum, DynaCon systems allow manufacturers to reconfigure layouts on the fly—no welding, no professional installers, and no extended downtime.

Whether you’re scaling up, shifting lines, or adapting to a new product run, DynaCon’s quick-change components, energy-efficient motors, and maintenance-free operation help keep operations agile and costs down.

Add Dynamic Conveyor to your planner to visit Booth SU-28016 at Pack Expo 2025 to see these solutions live. Discover how a smarter, simpler conveyor system can free up your floor space, your team’s time, and your capital budget.

- Mechanical Design Engineer - February 8, 2026

- Holiday Cheer at the Office: A Potluck to Remember! - December 29, 2025

- Solving Packaging Bottlenecks with a DynaClean Vertical Z Conveyor - December 15, 2025