The Company

ITW Deltar, a division of Illinois Tool Works (ITW), is a leading manufacturer of automotive headrest guides based in Lakeville, Connecticut. The company holds a dominant position in the North American automotive market, supplying 98% of Ford’s and 85% of Toyota’s headrest guide components. This strategic market share underscores ITW Delta’s reputation for quality, reliability, and innovation in automotive interior components.

Challenge

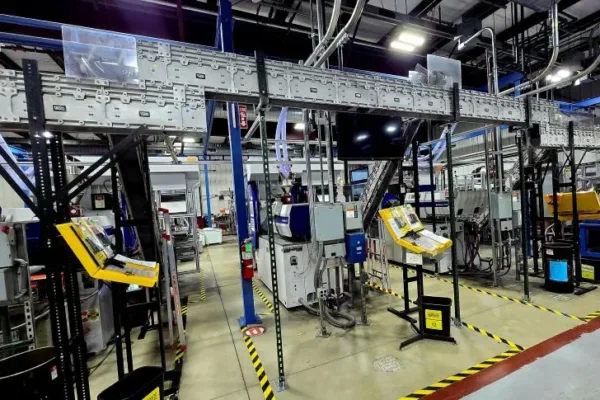

As part of a major plant consolidation and automation initiative, ITW Deltar needed conveyor solutions that fully automated the process of transporting parts from mold machines to assembly. Their current process had operators taking 20-pound totes of parts upstairs, adding time and potential for worker injury. While working to automate the manufacturing process, it was important to maintain clear aisleways for operators to access the molding machines without walking through a maze of additional equipment. The company sought to streamline operations across its Lakeville, CT facility.

Solution

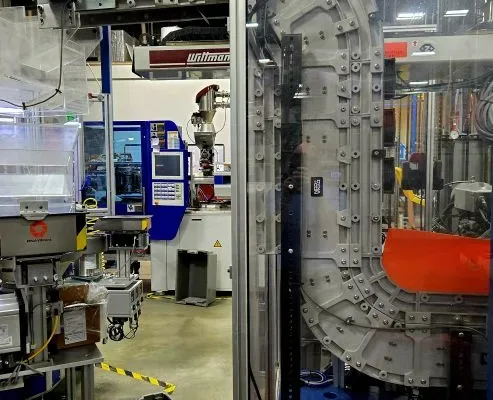

In 2020, ITW Deltar implemented its first set of DynaCon modular conveyor systems for manufacturing automation to support the consolidation of two plants and enable inline automation between molding and assembly. The flexibility of the DynaCon system allowed for seamless integration into the new layout and provided the adaptability needed for future modifications. Over the next six years, ITW Deltar continued expanding its use of DynaCon conveyors to support growing automation efforts.

Overhead conveyor systems allowed for clear aisle ways for workers to easily access mold machines. The ability to take the conveyor system from a flat configuration to a 90° vertical system to meet heights of 84” was crucial to their success.

Results

- Scrap Reduction: Scrap rates dropped from 4% to just 1.5%, significantly improving material efficiency.

- Increased Throughput: Automation and inline processing boosted production capacity. Allowing the company to take on new business.

- Labor Optimization: Reduced manual handling and labor costs, with some employees redeployed to higher-value roles.

- Enhanced Safety: Manual transport of 20 pound totes was eliminated, and no lost-time injuries have occurred in 3–4 years.

- Space Efficiency: Vertical conveyors reaching up to 84 inches preserved floor space and aisle access.

- Low Maintenance: Minimal upkeep required over six years of operation.

- Future-Ready: Modular design supports ongoing reconfiguration as product lines evolve.

- World Class Operation: ITW Deltar is recognized all over the globe as a world-class automotive manufacturing plant.

With the addition of automotive manufacturing conveyors from Dynamic Conveyor, ITW Deltar reduced scrap rates, improved throughput, and optimized labor use.

Why DynaCon

ITW Deltar cites the modularity, ease of use, and long-term value of DynaCon conveyors as key reasons for their continued investment—despite a higher initial cost. The ability to pre-assemble systems simplified installation, while adding guarding enhanced operator safety.

Looking Ahead

With the automotive market currently flat, ITW Deltar is actively quoting new business and planning to expand its use of conveyor systems from Dynamic Conveyor, including additional box indexers and fillers for direct ship products. The company strongly recommends Dynamic Conveyor solutions to other manufacturers.

“The rigidity of other conveyors would never have allowed us to be successful in this automation initiative. I highly recommend these conveyors to other manufacturers who are seeking adaptable, efficient, and future-proof automation solutions.” said Philip Dunn, Manufacturing Engineer at ITW.

- Dynamic Motion Group Acquires Versatile Fabrication - February 18, 2026

- Holiday Cheer at the Office: A Potluck to Remember! - December 29, 2025

- Solving Packaging Bottlenecks with a DynaClean Vertical Z Conveyor - December 15, 2025