Portability & flexibility for configuration & reconfiguration

One of the major benefits of a DynaCon conveyor is that it offers you complete flexibility for reconfiguration and repurposing of your conveyor system as the needs of your business change. But there are so many more reasons why DynaCon modular conveyors are the superior choice when looking for a custom conveyor system.

Configurations

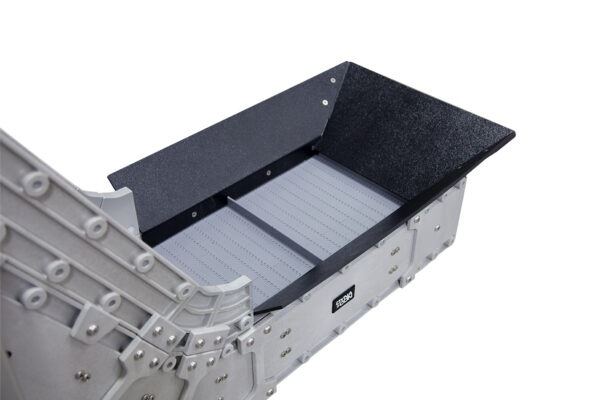

Flat Conveyors

Flat conveyors meet the needs of a wide variety of applications and integrate seamlessly with other Dynamic Conveyor lines. Easy to lengthen, shorten, add an angle, or reconfigure on the fly with its modular design.

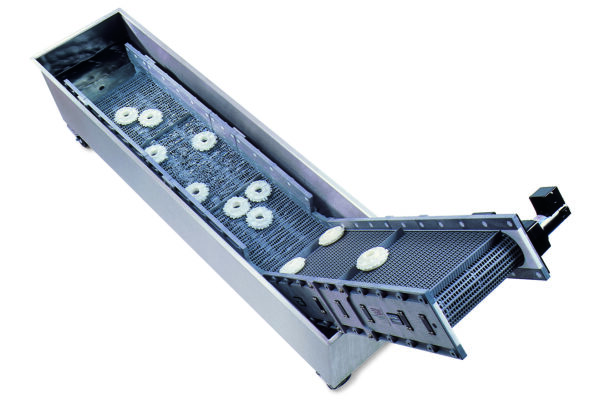

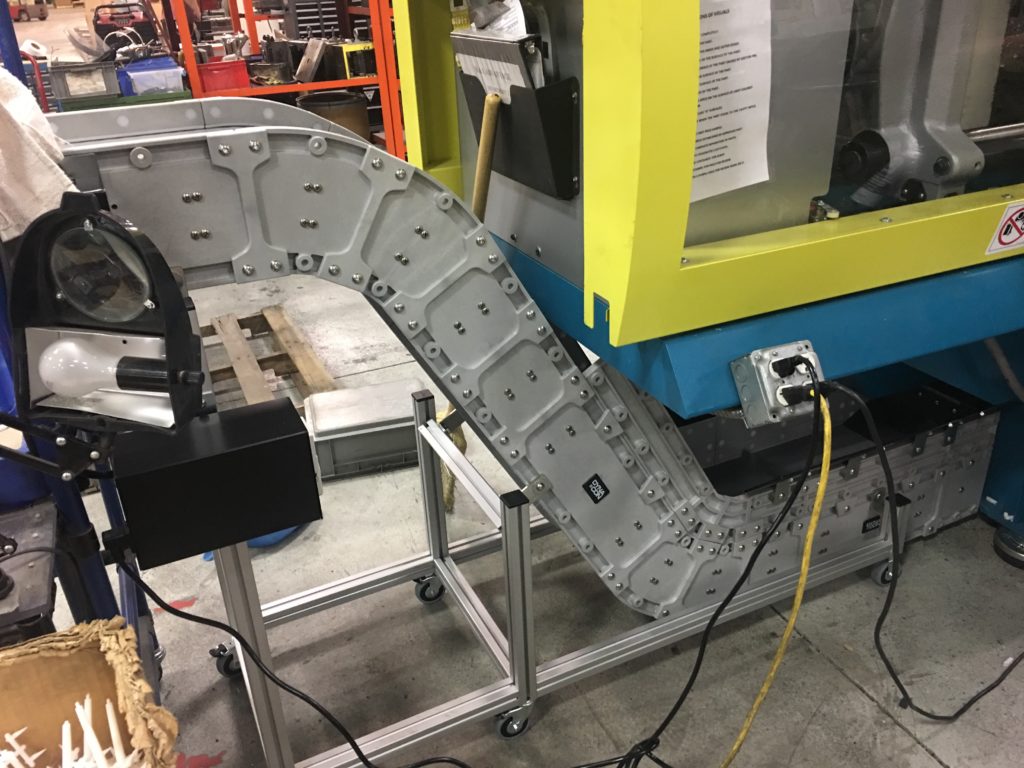

Z-style Incline Conveyors

Z-style incline conveyors can be designed and built using angles ranging from 30o to 90o, creating just the right configuration to get your product where it needs to be.

Vertical Conveyors

Vertical conveyors give you the ultimate ability to work within small footprints, optimizing floorspace and efficiently conveying product to its final destination. They also make an ideal replacement for bucket elevators.

From simple to fully customized, DynaCon conveyor solutions are built for your unique needs.

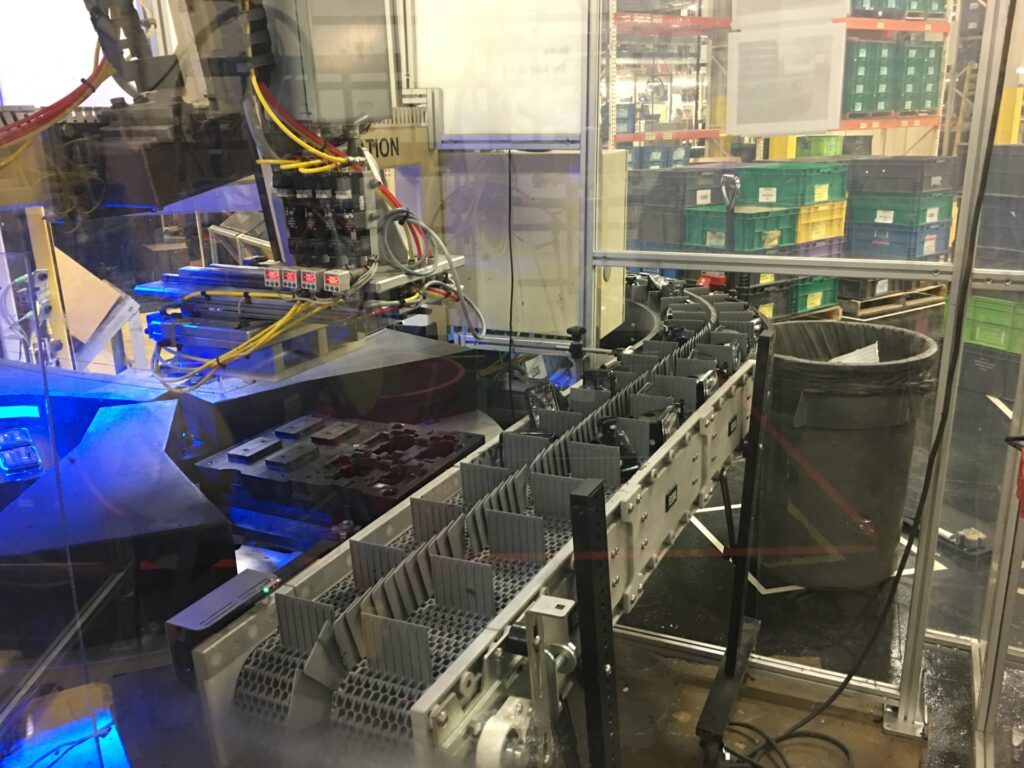

Automated parts filling conveyor with accumulation hopper

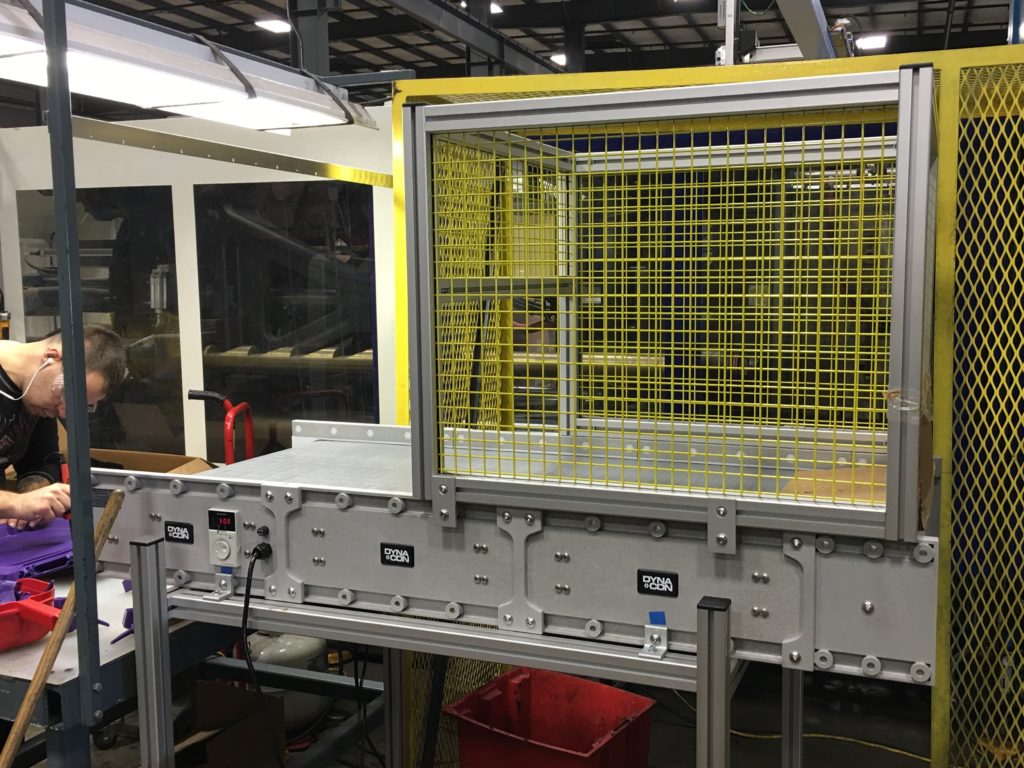

Dual z-style incline conveyors with reject conveyor

DynaCon vertical conveyor fed by vibratory bin hopper

Rapid plastic parts cooling with conveyor in water tank

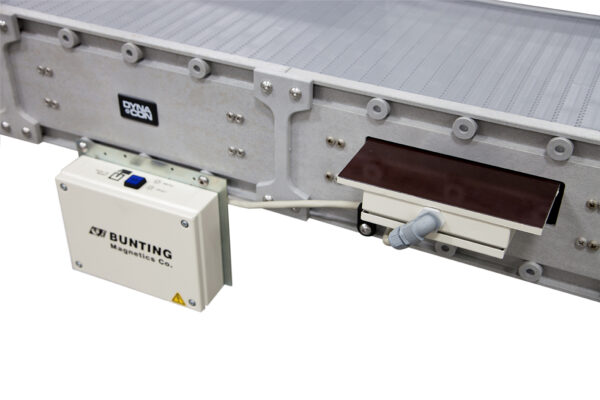

Accessories

- A variety of options are offered to meet your specific application needs, including but not limited to metal detection, ionizers, cooling fans and water bath tanks

- DynaCon conveyors are easily adaptable to meet ISO clean room conveyor requirements

- Chutes, hoppers, diverting arms and parts transferring accessories are available to meet all of your conveying needs

- Additional accessories like E-Stop and Photo Eye Stop bring added safety and efficiency to your facility

Designed for a manufacturer’s changing needs – and budget

DynaCon conveyor systems can be built in a variety of configurations using horizontal, vertical, and z-style decline and incline conveyor modules. When your needs change, save time and money by simply reconfiguring your existing conveyor modules. DynaCon plastic belt conveyor systems are designed and built to your specifications, and include a 5-year warranty.

Endless configurations

- Conveyor modules of varying lengths (up to 100 feet) and widths (from 4″ to 72″ wide) connect to form completely custom conveyor systems

- Configurations include flat, vertical, and z-style incline conveyor modules

- Re-arrange lightweight plastic conveyor modules on portable casters

- Add accessories and additional modules anytime for a dynamic system that adapts to your changing needs now and in the future.

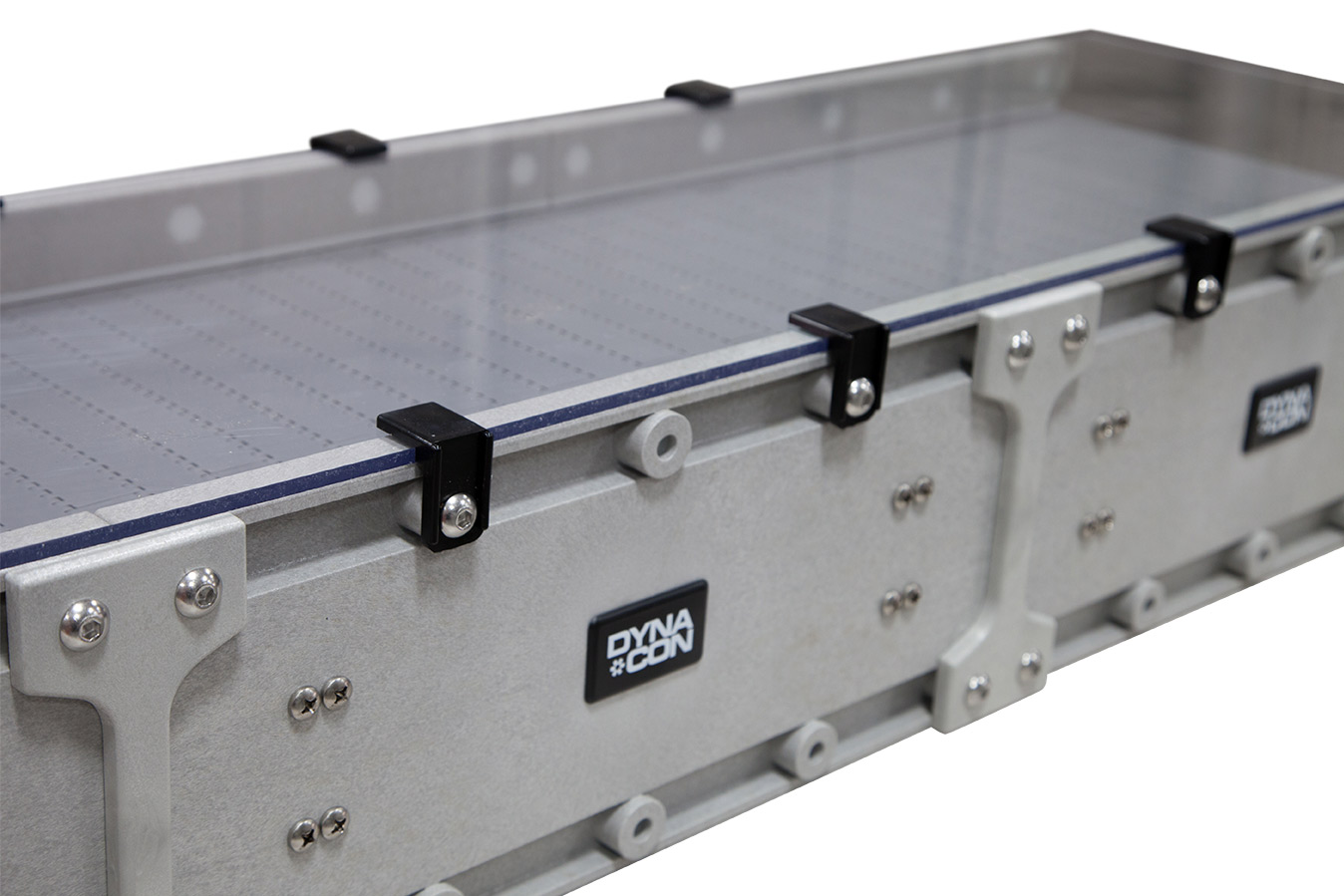

Quality built modular plastic belt conveyors

- Plastic conveyors constructed from lightweight, sturdy, high-impact polycarbonate, resulting in both portability and durability

- Interchangeable plastic link belting styles like flat top, flush grid, rubber top, mesh top and accumulation conveyor belts to meet the needs of your operation

- A variety of frame options, many with casters, allowing you to to keep your conveyors portable

- Maximize floor space and increase efficiencies with overhead conveyors by hanging DynaCon conveyors from the ceiling

- DynaCon modular plastic belt conveyors include a 5 year warranty

ROI

Low Cost of Ownership

Low cost of ownership is a crucial consideration for businesses when making purchasing decisions. It refers to the total cost of owning and operating a product or asset over its lifespan. Low cost of ownership can help to reduce expenses, increase profitability, and promote sustainable and responsible asset management. Achieving a low cost of ownership can be accomplished by selecting high-quality, durable products and implementing effective planned maintenance programs. By prioritizing a low cost of ownership, businesses can save money and resources while also contributing to a more sustainable future.

Product lines from Dynamic Conveyor contribute to low cost of ownership in a variety of ways:

- Modularity: DynaCon conveyors are designed with a modular philosophy allowing them to be reconfigured to meet specific and changing needs of our customers business, which can help to reduce costs by eliminating need to purchase new equipment in the future.

- Quality Components: We utilize high quality components in all our designs. This leads to a durable conveyor system built to last. Reduces replacement parts costs, maintenance costs, and minimizes spare parts inventory needing to be carried.

- Low Maintenance Costs: The design simplicity of our conveyors minimizes the number of components and wear items in a conveyor, minimizing repairs and preventative maintenance. Additionally, we utilize non-tensioned belts in all our designs eliminating the maintenance time to continuously track belts.

- Energy Efficiency: Standard motor packages include DC brushless motors, with reversing and variable speed capabilities. These motor packages reduce energy consumption by an average of 30% year-over-year relative to a standard 3 phase AC motor package.

- Easy Integration & Installation: Most of our DynaCon conveyors can be easily assembled onsite by your own staff, which can help to reduce costs associated with additional onsite fabricators and installers. When project size requires outside support, our systems are easily installed and integrated with existing equipment reducing your installation costs.

We’ve Built Conveyors For:

English

English Español

Español Français

Français